Smart Process Control, Faster Batch Production – As additive manufacturing scales into batch production, efficiency, quality control, and process transparency are critical. Farsoon addresses these needs with its dedicated Manufacturing Execution System (MES)—a digital solution that streamlines production, cuts labor costs by up to 70%, and enables a single operator to manage 12 machines simultaneously.

Covering six core modules, the system brings full workflow transparency and intelligence to your industrial 3D printing.

01 Production Management: Intelligent Scheduling

The system’s central module automates planning, scheduling, and monitoring of the build jobs. It helps automate production planning based on order priority, machine and material availability, visualized through an intuitive Gantt dashboard. Real-time adjustments keep machines running continuously, improving throughput and on-time delivery.

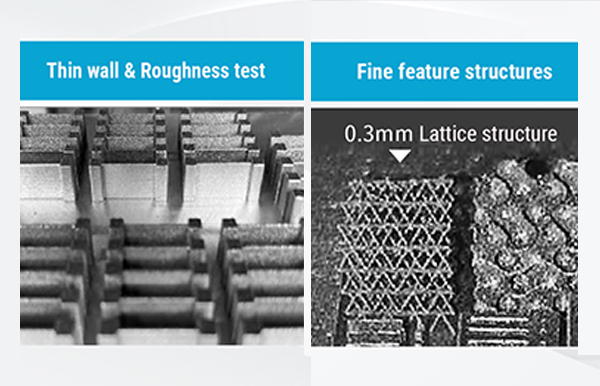

02 Quality Management: Full Traceability

Integrated real-time monitoring captures layer-wise quality data during printing. All key data like defects and dimensional accuracy is stored, allowing complete 3D process reconstruction for root-cause analysis. A visual quality dashboard displays yield rates and defect trends, enabling closed-loop quality control.

03 Material Management: One Code, Full Trace

Each material batch receives a unique ID. Scan-based tracking covers intake, consumption, and inventory, slashing quality traceability time from hours to minutes and ensuring full material accountability.

04 Equipment Management: Streamlined Maintenance

Monitor machine status, operational hours, and key metrics in real time. The system helps detects maintenance needs, logs all service actions, and helps prevent unplanned downtime—extending equipment life and sustaining continuous production.

05 Alarm Management: Instant Response

Safety and operational parameters of both the printer and filtration systems are monitored continuously. Once preset safety thresholds are exceeded, alerts are triggered immediately via multiple channels, enabling rapid intervention to reduce risks and maintenance costs.

06 Parameter Monitoring: Proactive Protection

Critical machine process variables such as chamber oxygen and pressure are tracked in real time with customizable limits. All historical data can be configurated, logged for compliance, inspection and safety reviews, ensuring a secure production environment.

07 Built for Integration and AI

Farsoon MES supports openness and compatibility: offering standardized APIs for connectivity with ERP, WMS, and SCADA systems. It is deployable across Windows, Linux, and cloud-edge platforms. The open architecture also allows future integration of AI models to enable predictive analytics and proactive process optimization.

By digitizing and intelligently controlling the entire production chain, Farsoon MES helps industrial manufacturers achieve full-process transparency, standardization, and high efficiency in production management. With MES system, customers can further reduce costs, minimize waste, and build a valuable data foundation for ongoing optimization and strategic growth.