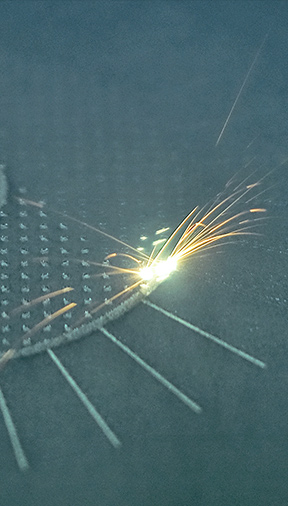

Metal laser powderbed fusion (MLPBF), also known as direct metal laser sintering (DMLS), is an advanced 3D printing technology uses powerful, high energy density fiber laser to melt metal alloy powder layer by layer:

1.Thin layers of metal powder material are recoated onto the powder bed using a rubber or metal blade depends on the metal alloy used.

2.The laser operates and melts the powder exactly within the defined area of the digital model section in each layer.

3.The 3D metal part forms with the recoating-melting process.