Titanium Bicycle Seat Stay Yokes

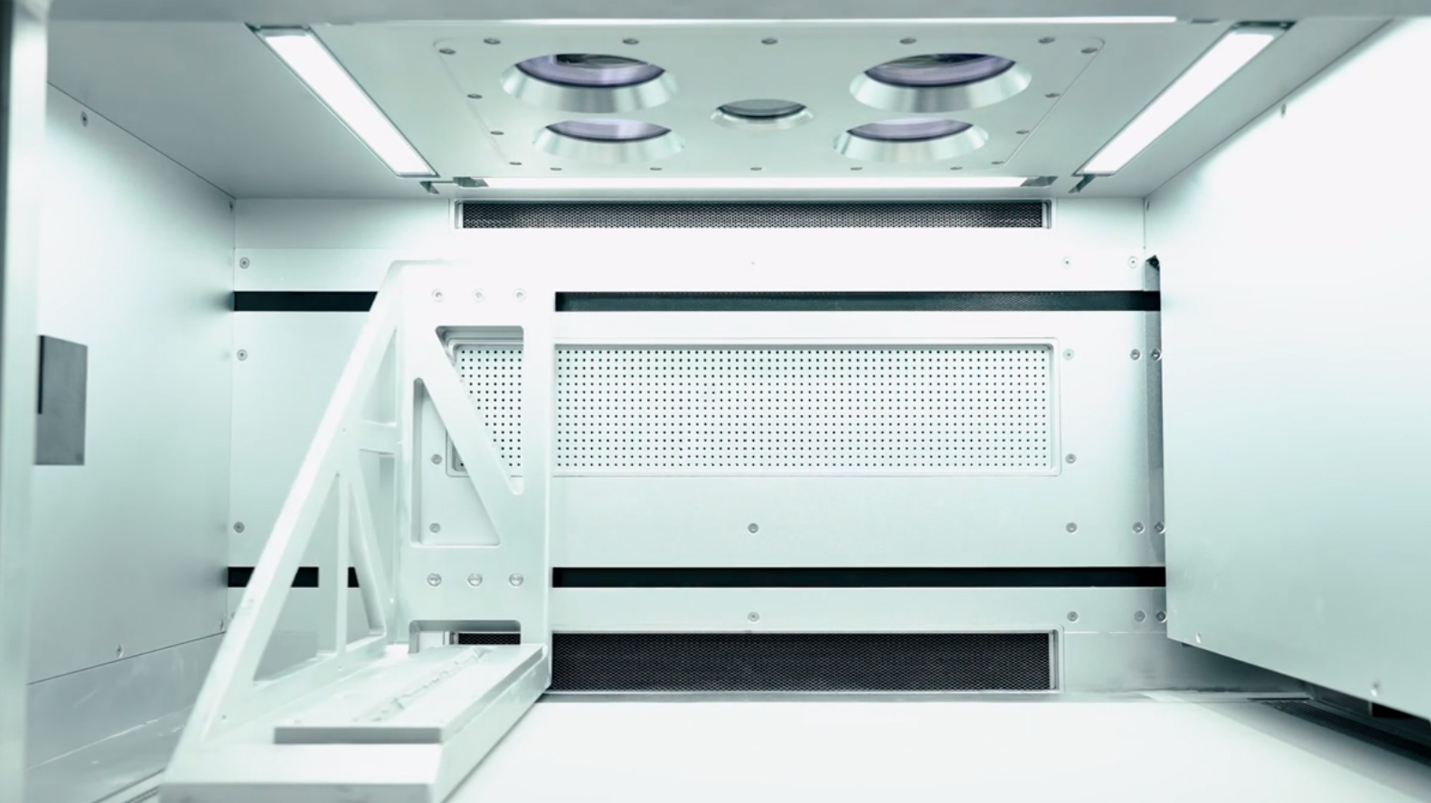

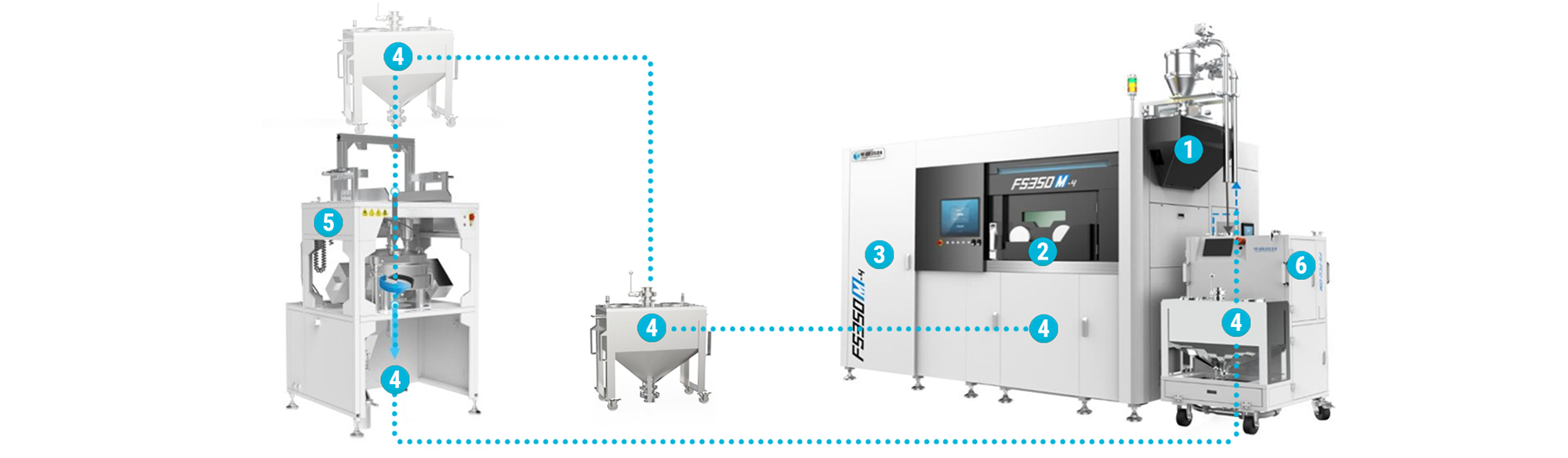

Machine: FS350M-4

Material: Ti6Al4V

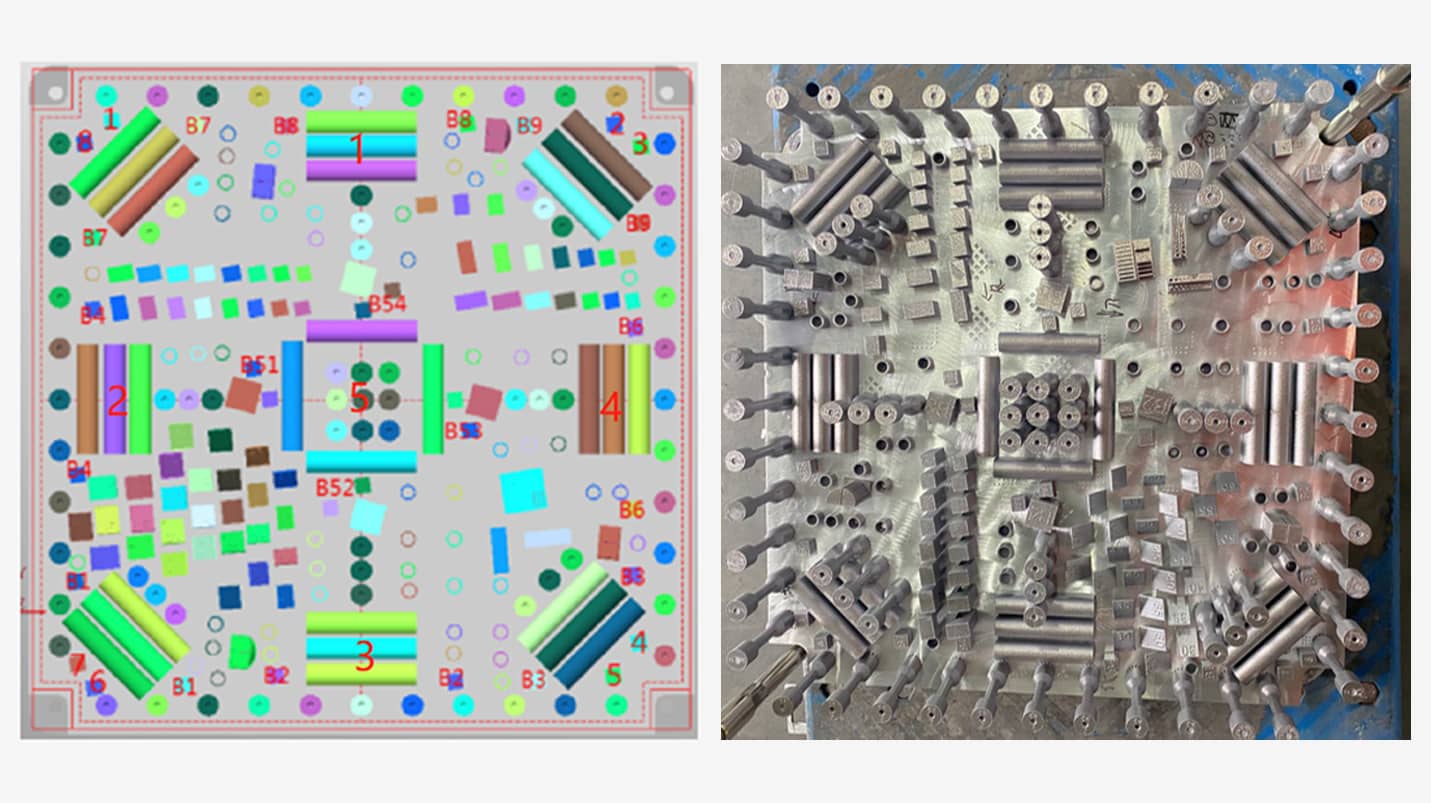

Size: 433 x 358 x 116 (H) mm (38pcs in one build)

Layer thickness: 0.06 mm

Build Time: 24 Hours

Batch production of titanium bicycle seat stay yokes using the FS350M-4 demonstrates a leap in efficiency and innovation. In just 24 hours, 38 components are 3D printed, achieving a 60% increase in efficiency compared to traditional casting methods. The flat aero tube design of these yokes not only streamlines production but also enhances cycling comfort by reducing the impact of the wheelset on the frame. This advanced manufacturing approach not only speeds up production but also contributes to a smoother, more comfortable ride.

VIEW CASE STUDY