July 2025, Stuttgart and Barcelona (GER/ESP)

Farsoon and Stark Future are already doing serial production of functional components for Stark’s electric motorbikes; the KLINGA project marks another milestone in this production partnership— highlighting scalability, quality, and precision of additive manufacturing for sharp-featured titanium components.

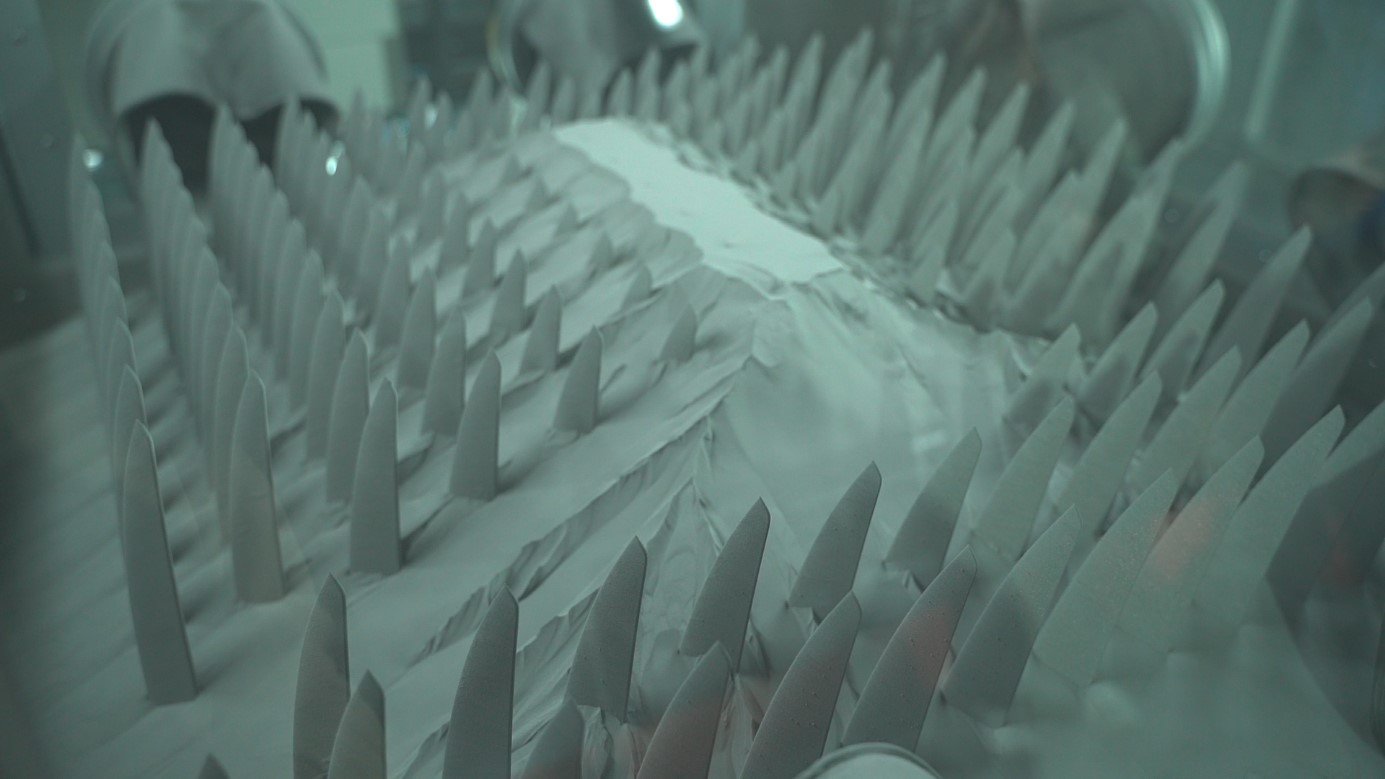

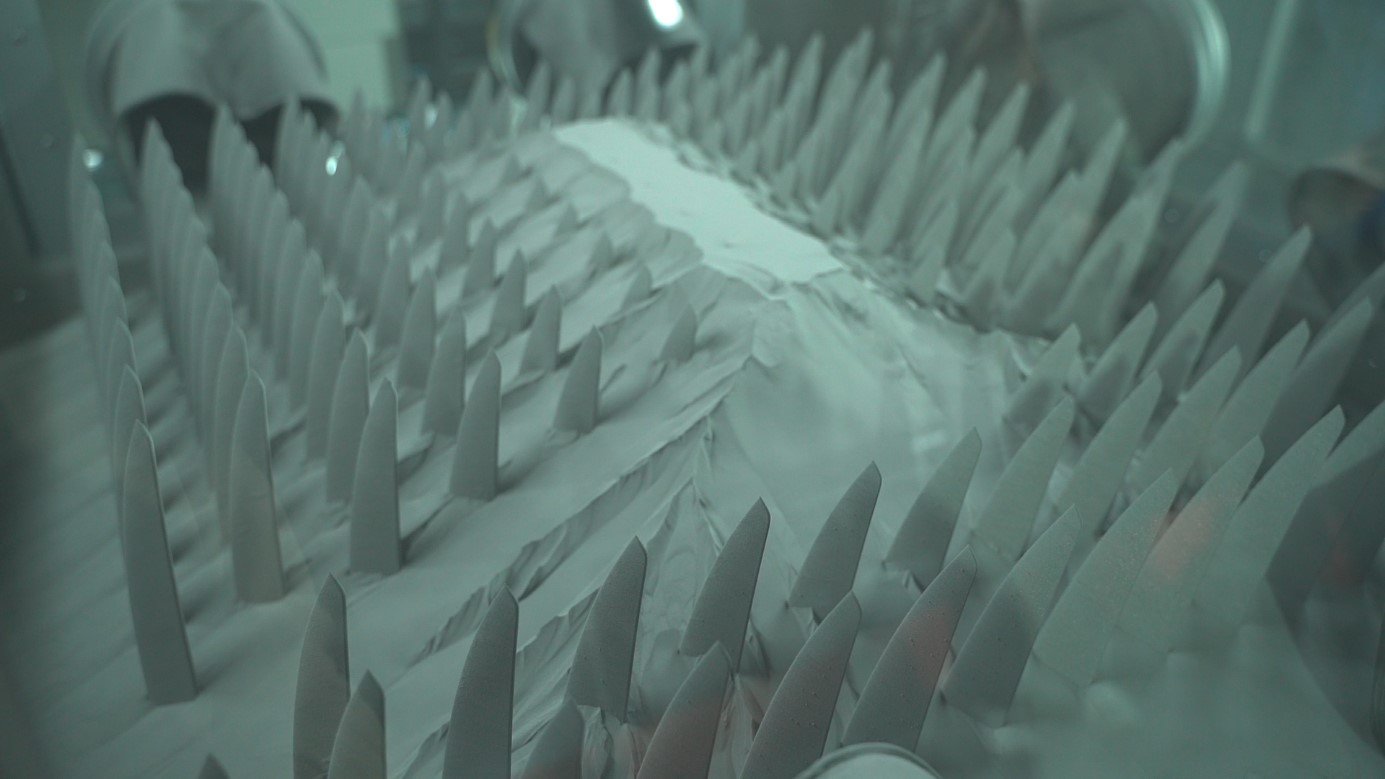

Photo of the KLINGA Sabre (height over 60cm)

Farsoon Europe GmbH and Stark Future proudly announce the completion of the KLINGA Project, a collaborative engineering initiative that produced more than 1,000 high-quality titanium parts using Farsoon’s industrial metal AM systems. Designed as both a test bench and engineering tribute, the project highlights Stark Future’s innovative spirit and Farsoon’s capability to deliver repeatable production with precision, quality assurance, and cost-efficiency.

The KLINGA Sabre—an engineering sculpture inspired by Stark Future’s electric motocross bike VARG—was not simply designed for form, but as a benchmark of what modern additive manufacturing can achieve. Featuring sharp angles, complex geometries, and a functional titanium moose-head bottle opener, KLINGA was built to push the boundaries of titanium 3D printing.

The sabre project encompassed full-scale validation of the AM process including:

– Process parameter development for titanium

– Design for Additive Manufacturing (DfAM)

– Support reduction and build strategy

– Adaptive layer thickness based on part height

– Repeatability and scalability of serial production

– Post-processing and part quality assurance

Full build plate of KLINGA Sabres

KLINGA Sabres under part breakout process in a FS811M Machine

Photo of the FS811M-12 with 12 lasers with a build cylinder size of 840 mm x 840 mm x 960 mm or 1700 mm in z height

The parts were printed on Farsoon’s FS811M platform, demonstrating the system’s ability to manufacture sharp-angled, complex titanium components with repeatable results. Notably, the same production quality and workflow can be replicated on the FS721M platform currently operated by Stark Future.

In a single 248-hour build, 188 KLINGA sabres were produced with an average build time of under 80 minutes per unit. The real breakthrough lies in the combination of engineering creativity and industrial performance—demonstrating Farsoon’s capabilities for consistent quality control, cost-efficient operation, and production readiness.

Quote from Stark Future:

“The KLINGA Project was a bold way for us to push boundaries—not just in design, but in manufacturing,” says Benjamin Cobb, Director Brand Communications at Stark Future. “Partnering with Farsoon allowed us to turn an ambitious idea into a titanium reality. It’s proof that large-scale, high-precision metal additive manufacturing is ready for serial production. It also validated our belief that 3D printing can deliver performance, quality, and sustainability—all at once.”

Quote from Farsoon Europe:

“The KLINGA Project is a great example of our collaboration with a visionary customer,” says Oliver Huizhi Li, Managing Director of Farsoon Europe. “From sharp-edged part design to titanium process optimization, this project reflects what’s possible when engineering ambition meets scalable AM technology. The quality results and process stability achieved in KLINGA reflect Farsoon’s commitment to delivering reliable machines, cost-per-part efficiency, and excellent service.”

About Stark Future

Stark Future S.L. is a leader in electric off-road motorcycles, headquartered in Barcelona, Spain. With a focus on performance, innovation, and sustainability, Stark Future is reshaping the future of powersports by integrating cutting-edge technology and design.

About Farsoon

FARSOON Technologies, founded in 2009, is a system supplier of industrial plastic and metal AM platforms. With open parameter strategy, high-performance hardware, and localized support via FARSOON Europe GmbH, the company empowers customers to scale additive manufacturing with quality, flexibility, and cost-efficiency.