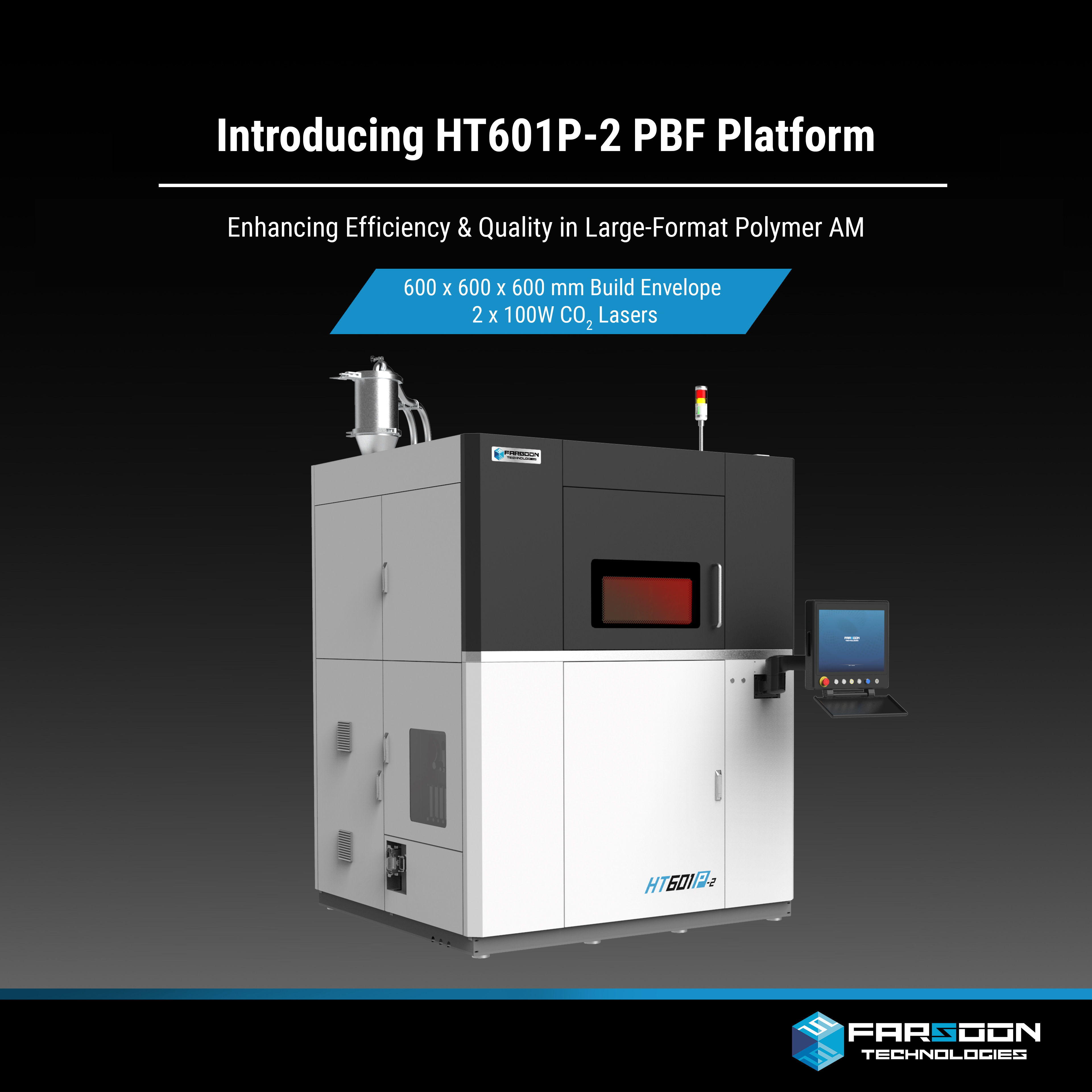

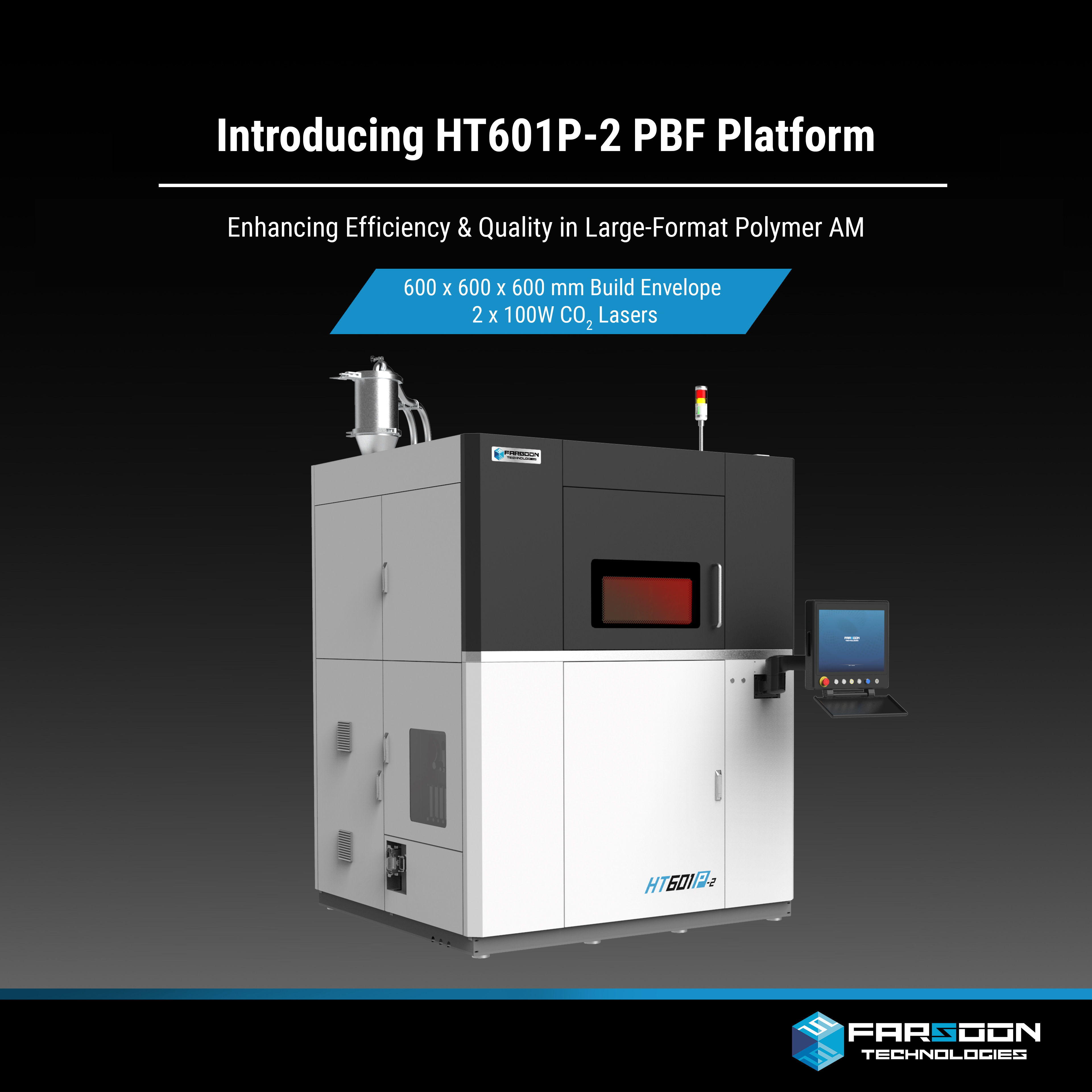

Frankfurt, Germany – Formnext 2025 – November 18th, 2025 – Farsoon, a global leader in industrial additive manufacturing solutions, unveiled the HT601P-2, a serial production ready, large-format polymer laser sintering system engineered for ultimate quality and efficiency. Building on the success of the Flight® HT601P-4 platform, the HT601P-2 continued to offer continuous production capability, advanced process control, increased level of automation to address the evolving needs of industrial manufacturing while being able to take advantage of the wide range of existing powdered materials available on the market for CO2 based SLS systems.

Serial production ready Large-format polymer PBF platform

The Farsoon HT601P-2 represents a serial-production-ready platform for large-format polymer powder bed fusion (PBF).

• Large-format: Engineered for industrial scalability, the system features a substantial 600 × 600 × 600mm cubic build volume, facilitating the production of large-scale components and highly efficient batch production of smaller parts.

• A Dual-laser system: This capability is enhanced by a robust dual-laser system, comprising two 100W CO2 lasers, which accelerates build rates to elevate throughput and reduce the cost-per-part. When benchmarked against standard SLS systems, the HT601P-2 demonstrates a marked increase in production efficiency, achieving outputs of up to 12 kg of final parts per day at a 12% nesting density from a full build. This high-throughput performance directly translates to a significantly reduced total cost of ownership, solidifying its value as a cornerstone for industrial additive manufacturing.

Uniform full-format performance

Farsoon’s HT601P-2 sets a new standard for large-format additive manufacturing, enabling a direct path to serial production. It ensures exceptional part consistency and maximizes productivity for both oversized components and high-density batch jobs.

• Full-Field Performance: The HT601P-2 delivers uniform properties across the entire build platform, maximizing equipment utilization and output.

• Unmatched Consistency: Advanced system integration ensures less than 5% mechanical variation, guaranteeing the quality and stability of both large-scale and batch-produced parts.

• Accelerated Industrialization: This reliability stabilizes part quality, reduces waste, and speeds up production certification for scalable manufacturing.

Advanced process control

• High-Precision Optics: Digital galvo scanners with dynamic focus maintain consistent laser spot size and energy density across the entire 600×600mm build platform, ensuring uniform sintering and isotropic part properties.

• Innovative Powder Supply: The unique top-loading and bottom-feeding system ensures dense, homogeneous powder layering through controlled, pressure-stabilized recoating, eliminating streaking and minimizing layer-induced defects.

• Comprehensive Thermal Monitoring: A multi-zone thermal control system maintains ±3°C chamber uniformity, with optional IR camera integration for real-time process documentation and quality validation.

Continuous Manufacturing Capability

The HT601P-2 features an interchangeable build cartridge for continuous production, drastically reducing non-productive downtime to maximize asset utilization and throughput. Its compact footprint enables high-density facility planning, significantly improving production yield per square meter and driving down the cost per part. With cartridge heating integrated into the HT601P-2 system, build cartridge costs and complexity are significantly reduced.

Versatile Material Capability for Advanced Applications

With chamber temperatures reaching up to 220°C, the HT601P-2 is engineered to support an extensive range of high-performance polymers, including PA6, PBT, PA11, PA12, and TPU, catering to demanding industries such as aerospace, automotive, and consumer goods, empowering manufacturers to push the boundaries of material performance and application diversity.

Ease of Operation for Industrial Environments

Engineered for seamless integration into large-scale production workflows, the HT601P-2 delivers exceptional operational simplicity through advanced automation and centralized control. Key features include:

• Advanced Powder Management System (PMS): Enables simultaneous powder recycling, mixing, and sieving for multiple HT601P-2 units, optimizing material usage and reducing manual intervention.

• Smart Production Line Integration: Streamlines the entire manufacturing process with centralized powder handling, automated build cylinder transfer, controlled part cooling, and efficient part breakout—enabling fully automated, high-throughput production.

These integrated systems minimize operator dependency while maximizing productivity, making the HT601P-2 an ideal solution for continuous, industrial-scale manufacturing.

Experience the Technology at Formnext 2025

Discover the HT601P-2 and explore Farsoon’s full suite of additive manufacturing solutions at Formnext 2025 in Frankfurt, Germany. Visit us at Hall 11.0, Booth E11 to see the 601P series in operation, and learn how our technologies can transform your serial production.

About Farsoon

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Farsoon´s subsidiary FARSOON Europe GmbH (Sindelfingen, Germany) provides the whole range of machine portfolio after technical confirmation in China, as well as local service and maintenance activities.