Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity, which is widely used in industries such as aerospace, automotive, shipbuilding, electronics. Its properties tend toward applications such as heat exchangers, water cooled molds, and electronic components. However, the vast majority of additive copper is currently based on alloys of copper, not the pure metal. Many applications can only be unlocked with low-oxygen, pure copper. Pure copper has a high laser reflectance rate of over 90% with standard Metal Laser Sintering (MLS) systems. It is difficult for the laser to continuously and regularly melt pure copper powder, which leads to issues such as interface failure and thermal cracking.

During 2017, Farsoon’s Application team joined hands with industrial partners to begin developing an advanced process to produce pure copper additive components using Farsoon’s metal laser sintering systems.

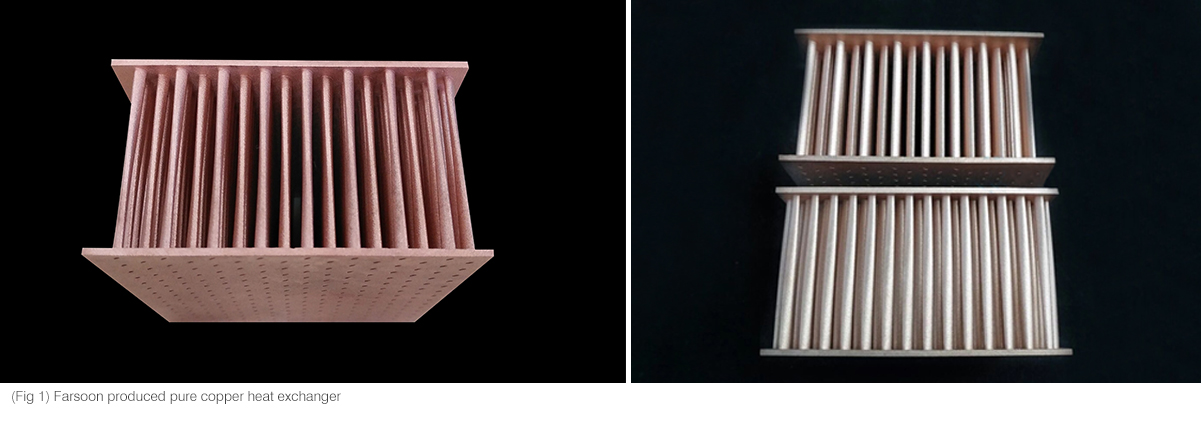

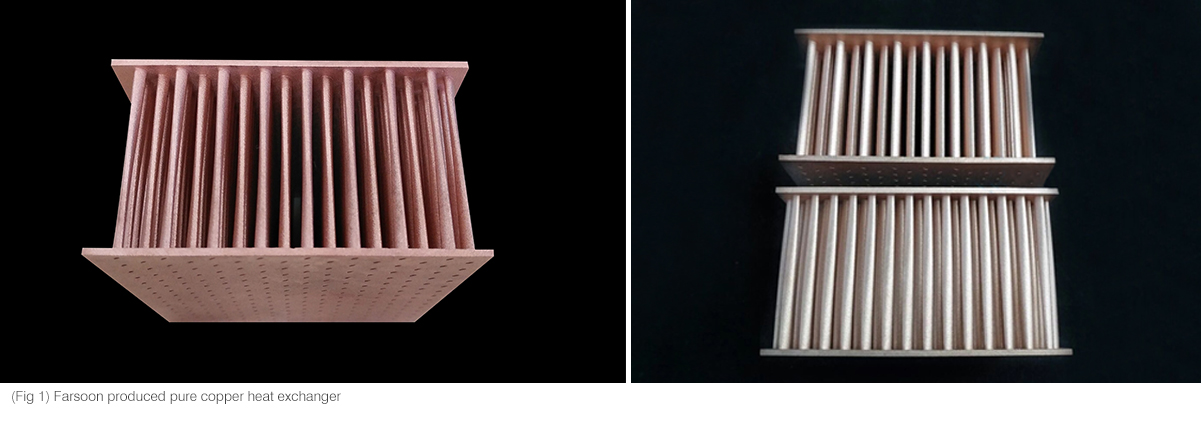

(Fig 1) Farsoon produced pure copper heat exchanger

One of the parts resulting from these collaborations was a pure copper heat exchanger (Fig 1) with complex spiral geometry and a wall thickness of only 0.5mm, this part was printed as a single piece using Farsoon metal laser sintering technology resulting in a far more efficient heat exchanger than that of one made by a traditional brazing process. The lightweight design reduces weight by over 30% and costs by 35%.

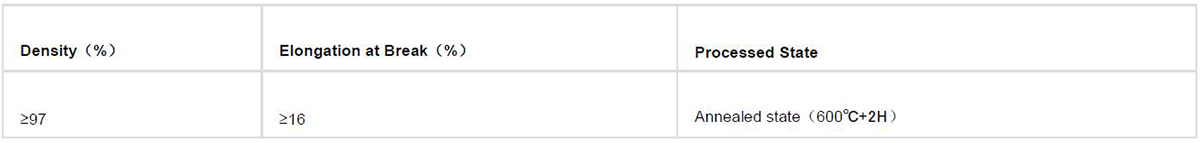

At present, all metal laser sintering systems of Farsoon can achieve high-quality, cost-effective pure copper processing. Farsoon’s Application R&D team conducted a large number of tests and obtained the appropriate scanning strategies and process parameters for pure copper. These parameters minimize the adverse effects of high laser reflectance of pure copper, in order to achieve the perfect part density, an optimized 3D printing process, and excellent performance. Farsoon’s unique parametric design and process meet the customized needs of users which will greatly expand the boundaries of 3D printing application in the future.

With the company philosophy “Open for Industry”, Farsoon is committed to providing customers with comprehensive additive manufacturing solutions, especially suited for new material development. Up to now, Farsoon has successfully launched 13 process parameters for metal powder sintering, and intensively developing specialized material such as tungsten, tantalum, pure copper and nickel-based alloys, providing multiple lightweight, functional and customized metal 3D printing material solutions for aerospace, automotive, medical, denture and other industries.

Farsoon’s Rare Metal Sintering Process Development Case:

(Top Left, Fig 2) Farsoon produced Tungsten Chip Radiator housing

(Top Right, Fig 3) Farsoon produced tantalum knee implant

In 2017, Farsoon cooperated with an aerospace industry partner to successfully achieved the production of 3D printed tungsten chip radiator housing (Fig 2). The porous structure’s design is more flexible and the processing cycle is greatly shortened due to the porous variable diameter structures being fabricated in a single piece without post-machining. The radiator housing features large pores of 1.5±0.02mm which transition into smaller pores of only 0.5±0.02mm. Part density achieved was over 96%.

In 2017, Farsoon cooperated with PLT and Chongqing Southwest Hospital to design and fabricated a 3D printed tantalum knee implant (Fig 3) using Farsoon’s FS271M MLS system. It is the world’s first medical application using tantalum for a knee implant. After repeated porosity tests and parameter optimization by Farsoon Application team and PLT engineers, the tantalum implant has been printed with good fitness and surface roughness, effectively filling the bone defect of the patient, ensuring the stability of the implant. The rough porous trabecular design enabled the autogenous bone to quickly grow into the implant’s pores obtaining long-term stability between the prosthesis and autologous bone.

Farsoon is now open for potential partners on development of pure copper and other specialized materials. Please contact globalinfo@farsoon.com for more information.