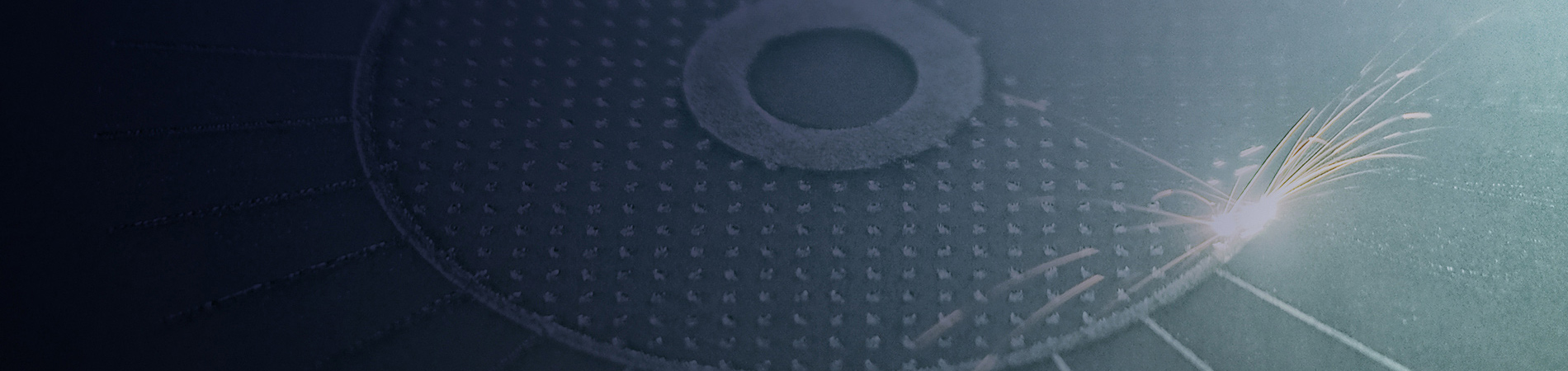

Changsha, China – July 3, 2025 – Farsoon Technologies, a global leader in industrial additive manufacturing solutions, has reached a significant milestone with 150 “Meter-Scale” large-format metal 3D printing systems (capable of building 1M+ parts) sales worldwide, serving clients across North America, Europe, and Asia-Pacific. Among these, the flagship FS1521M series—featuring build envelope up to 1530×1530×1650mm and up to 32 x 500W lasers —has seen 20 sales, positioning Farsoon as a front-runner in meter-scale metal additive manufacturing. These systems are now integrated into full-cycle manufacturing workflows, from R&D to serial manufacturing, enabling industrial users to achieve breakthroughs in productivity, performance and cost efficiency.

Figure 1: Farsoon Meter-scale metal 3d printing systems.

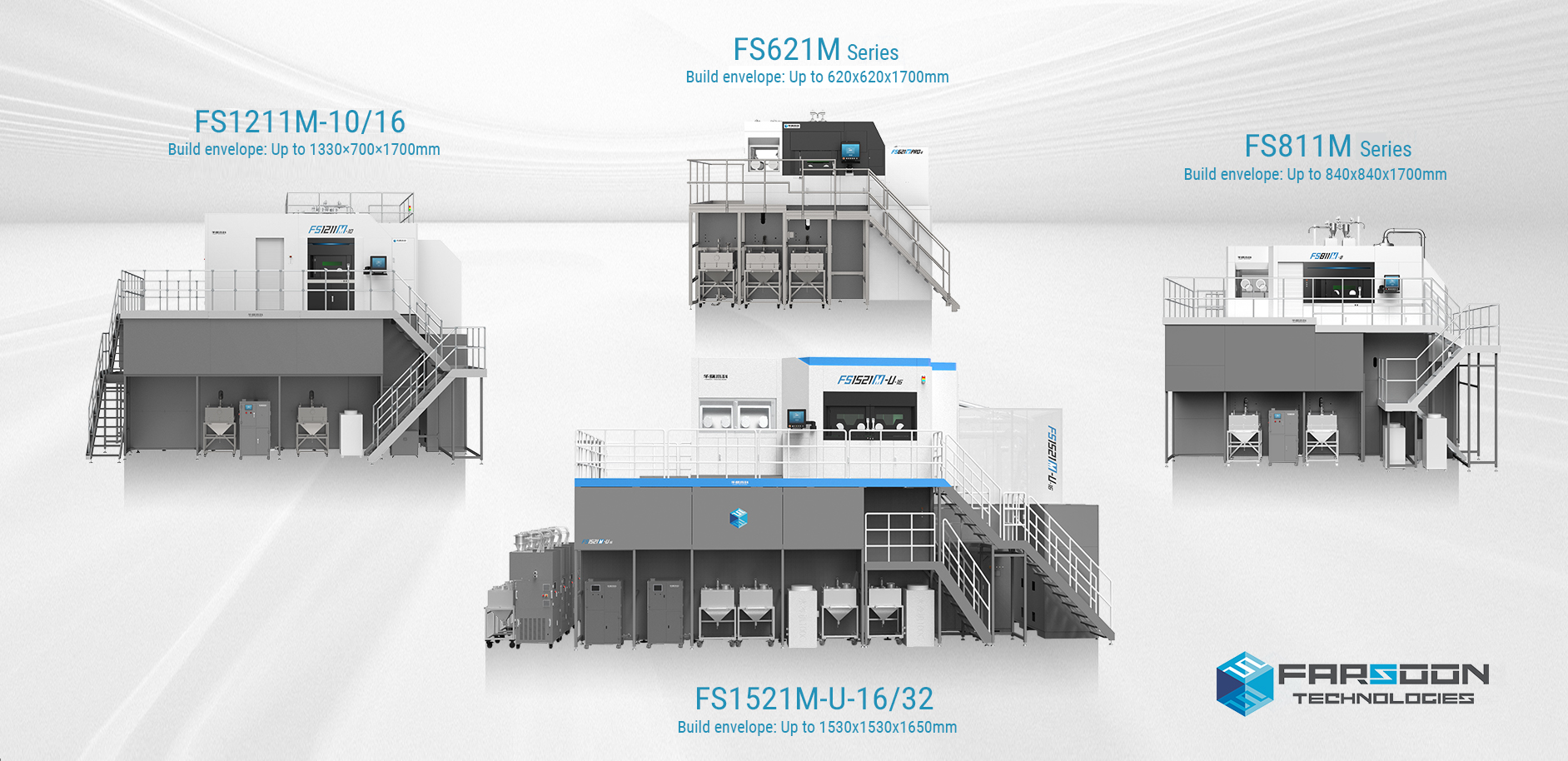

The rapid adoption reflects growing demand for large-format, high-throughput metal AM in sectors like aerospace (e.g., engine components), where Farsoon’s technology has evolved from a prototyping tool to a production-line staple. Pioneering users, including Falcontech, have established dedicated production lines with nearly 40 of Farsoon’s meter-scale metal systems since 2019 to meet batch manufacturing demands of end-use parts.

Figure 2: Farsoon Meter-scale metal 3d printing systems installed at Falcontech. Image courtesy: Falcontech

With installations spanning OEMs, tier-1 suppliers, and research institutions, Farsoon’s large-format metal systems are driving AM industrialization. The FS1521M series in particular has gained traction for applications like titanium structural components and copper alloy thermal systems, where size and precision are critical.

Technical Advancements Addressing Industrial Challenges:

The FS1521M series tackles critical production hurdles through five core innovations:

1. Dual-layer airflow system solves smoke & particle removal challenges across ultra-wide build areas, ensuring process stability.

2. High-capacity powder management system achieves 360L/H total recycling efficiency (via 4× 90L/H modules), enabling continuous production.

3. Multi-laser calibration achieves high precision of ±0.05mm guarantees part consistency in large builds.

4. The MES platform reduces labor costs by 70% through centralized production management of up to 12 machines per operator.

5. Farsoon’s advanced software suite ensures real-time monitoring and traceability, meeting stringent manufacturing standards in aerospace, oil & gas and more.

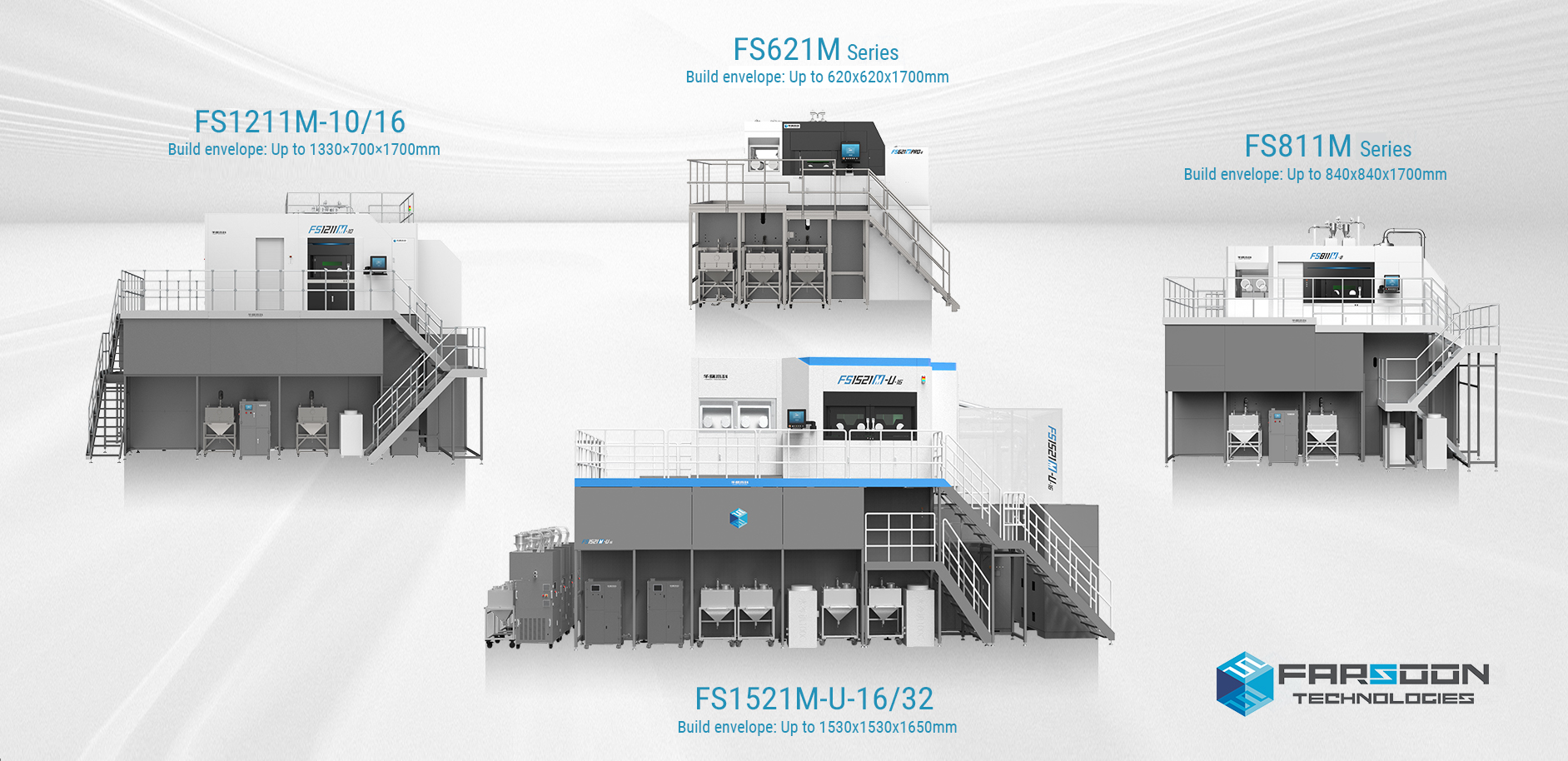

Innovative solutions for Materials & Processing:

Farsoon Technologies’ Meter-scale metal technology focuses on high-performance material and process R&D for aerospace applications, addressing extreme demands for high-strength, heat-resistant, and lightweight components. With 40+ certified metal PBF material processes, Farsoon delivers enhanced precision and stability, providing end-to-end solutions—from material development to part performance—for critical aerospace structures.

To tackle industry challenges, Farsoon has pioneered:

• “SRS” Support-Reduction System: Enables 10° minimum support angles (15° for inverted cones), cutting material costs and post-processing time while maintaining density.

• Speed Optimization: Improves large-format metal AM productivity without compromising quality through multi-system enhancements.

• Large-Scale Copper Alloy Solutions: The FS621M-Cu, solves high-reflectivity material challenges, enabling stable printing of meter-scale copper components.

Figure 3: Farsoon’s Material & processing development for large-format aerospace applications.

Farsoon’s Meter-scale Metal Systems redefines production-level metal 3D printing with its large-format, efficiency and enhanced cost-performance. For inquiries about Farsoon’s large-format metal AM solutions, contact: globalinfo@farsoon.com.