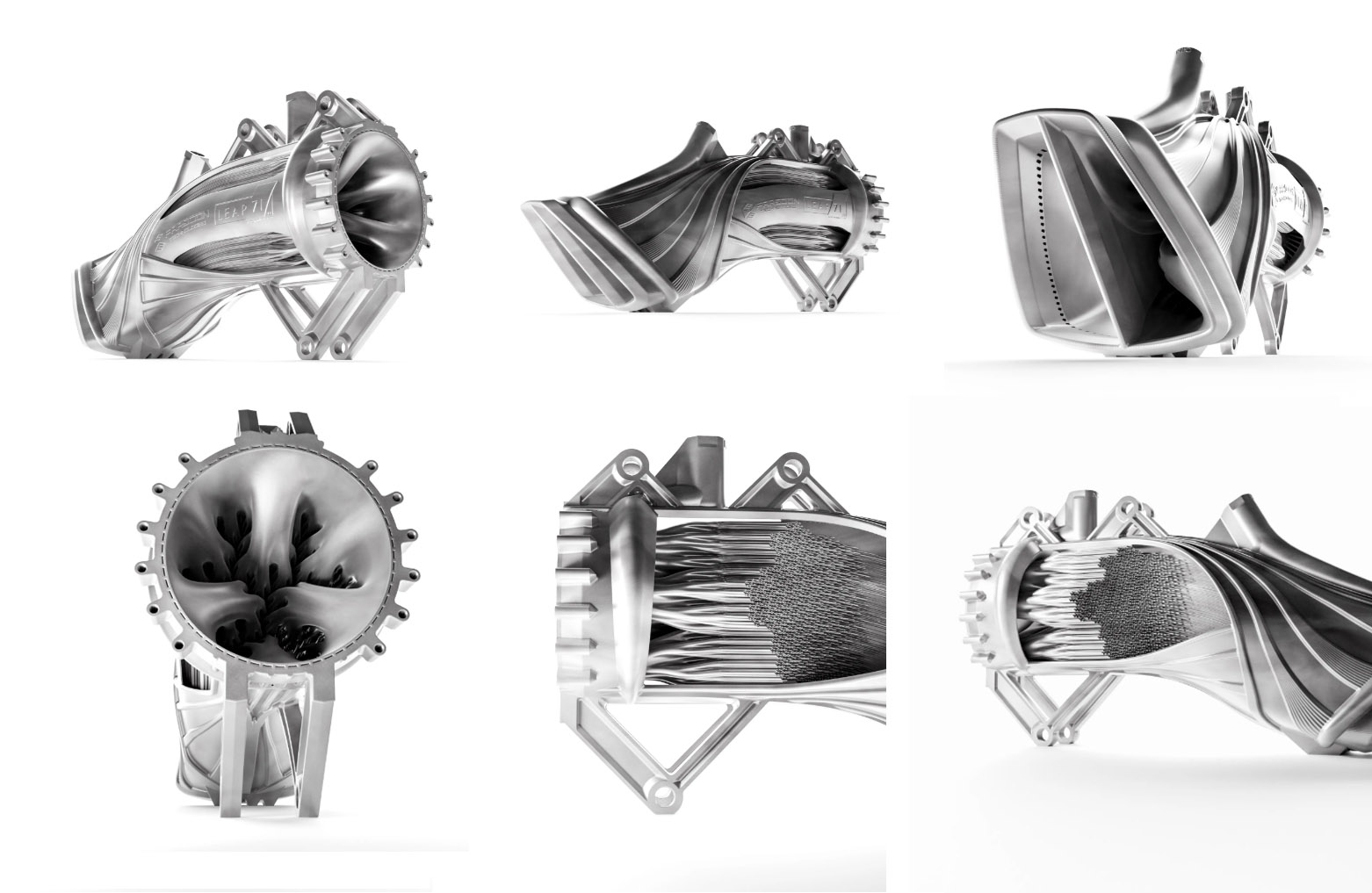

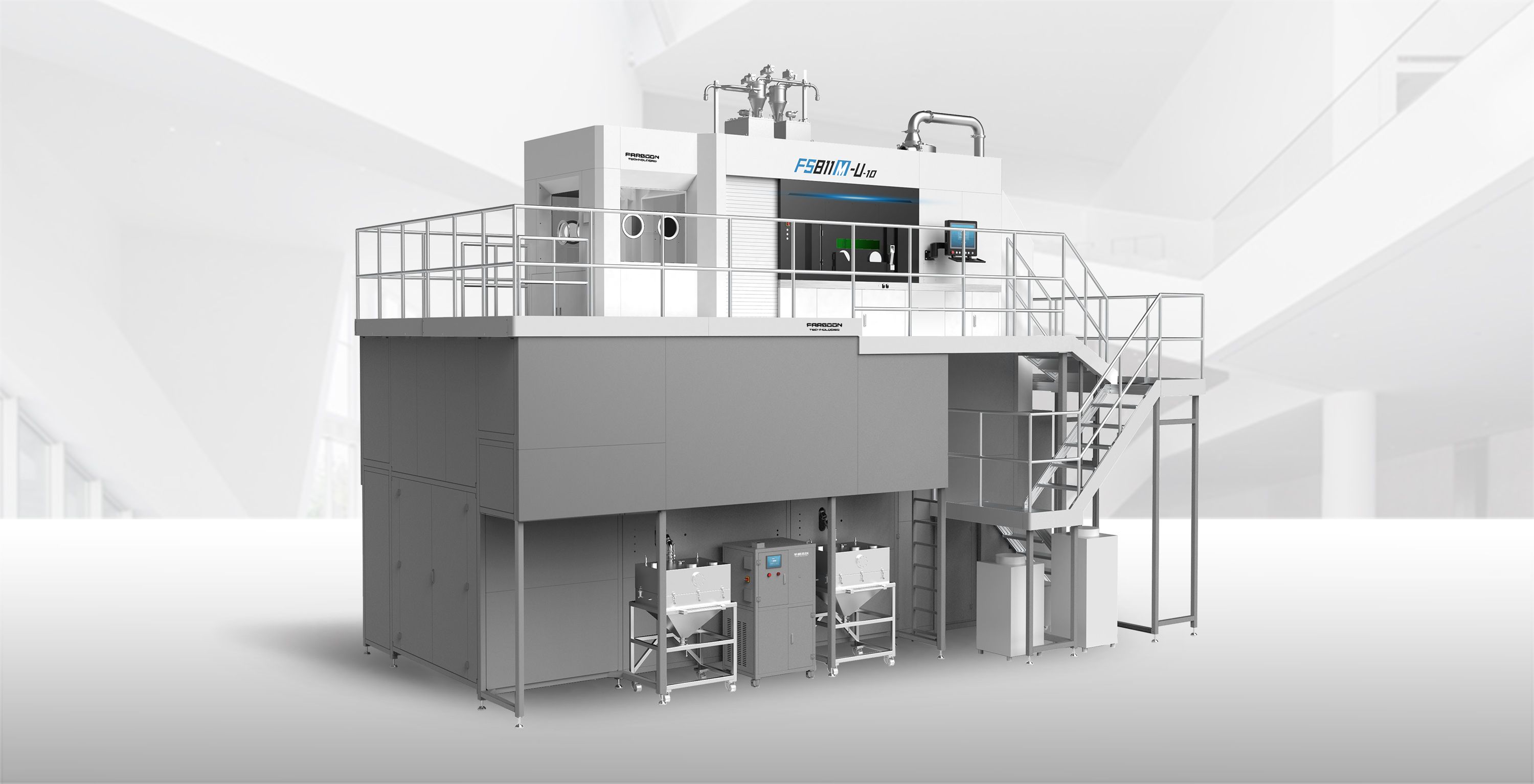

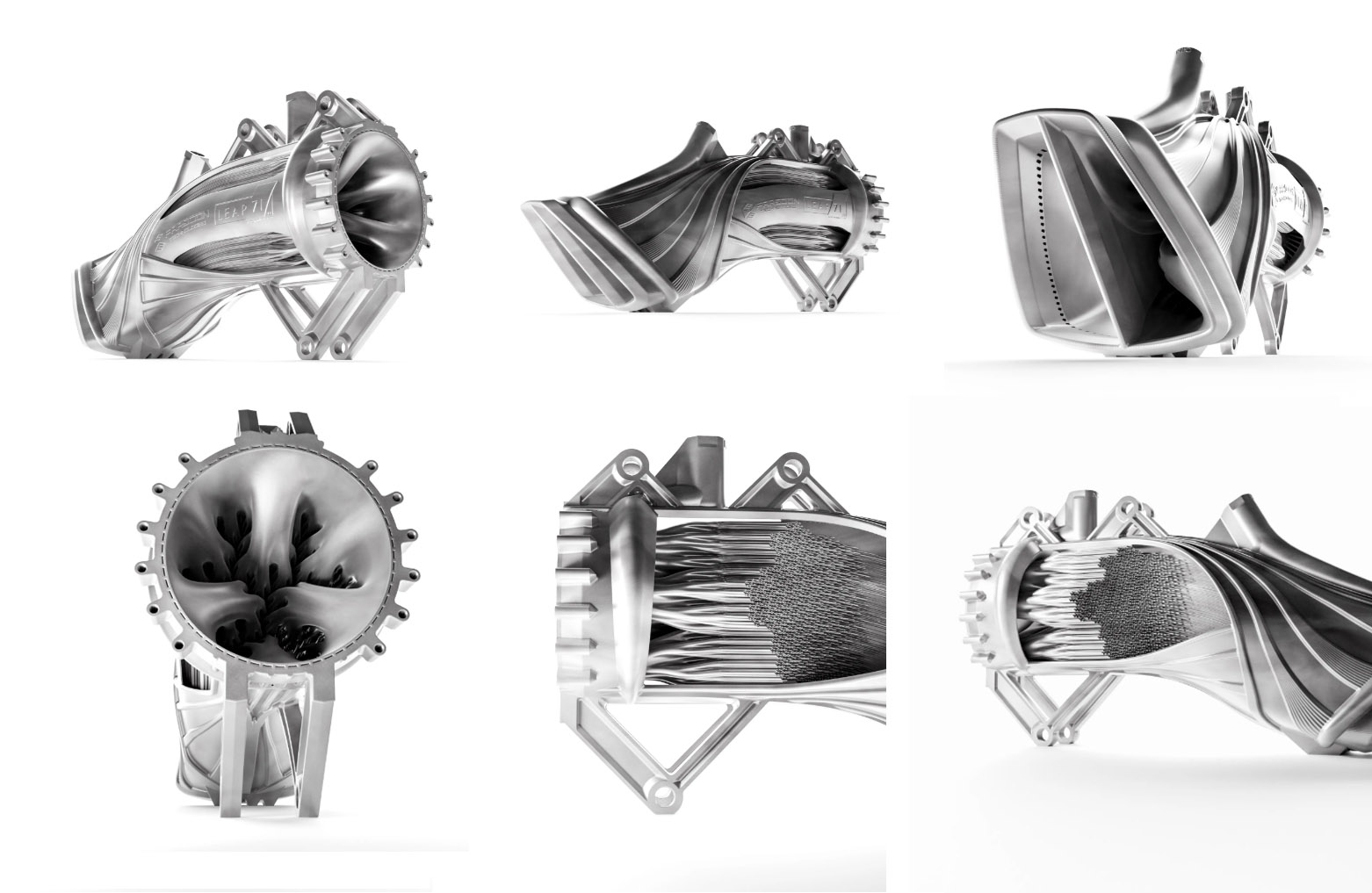

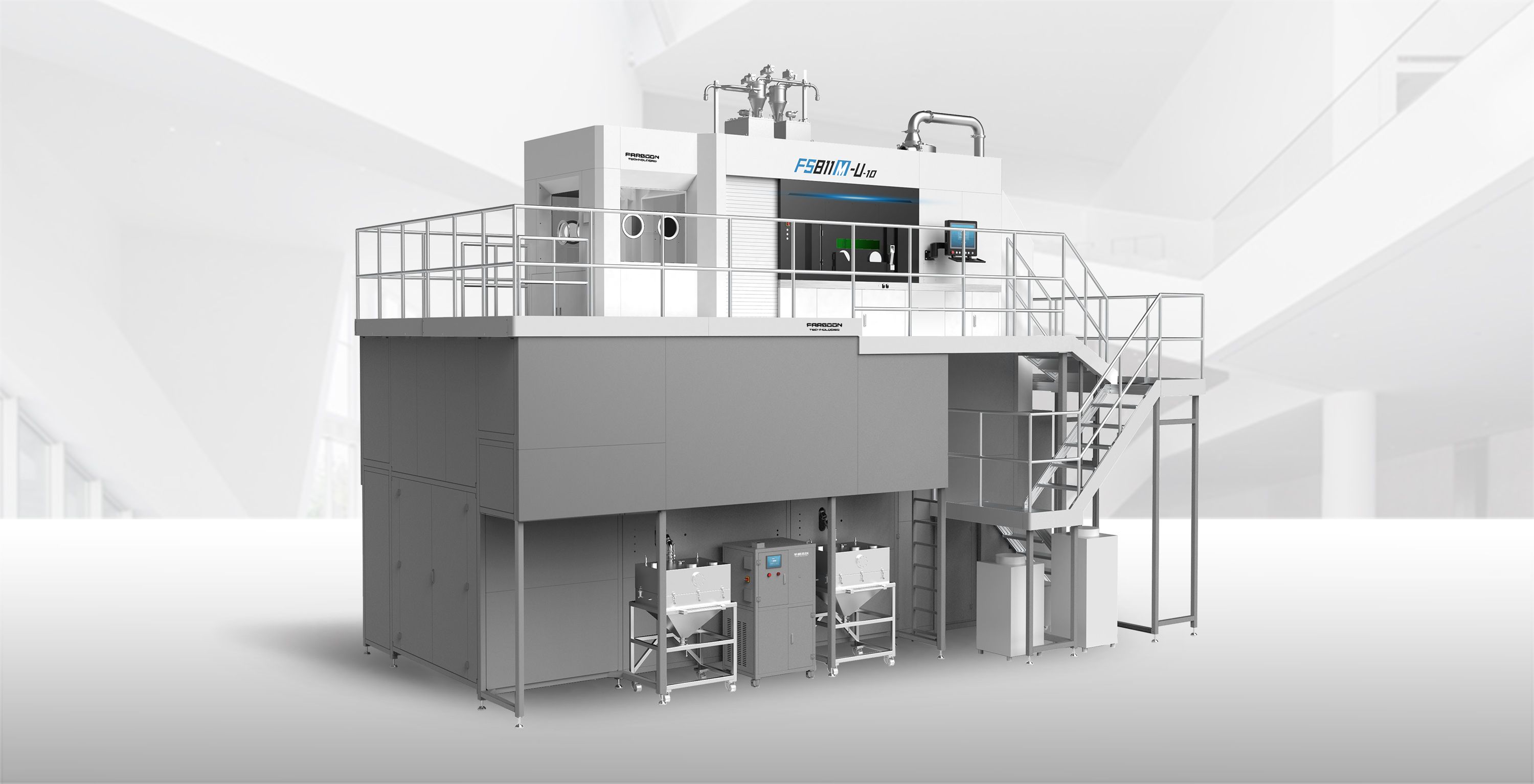

Dubai, UAE/Changsha, China, November 12th, 2025: Achieving single-stage-to-orbit flight — lifting off from a runway and reaching orbit in one continuous ascent — has long been one of aerospace’s most elusive goals. LEAP 71 and Farsoon Technologies have taken a tangible step toward that future with a large-scale hypersonic precooler concept: a key enabler for air-breathing launch vehicles. The 1.5-meter-tall component was computationally designed by LEAP 71’s Noyron system and realized on Farsoon’s FS811M-U-8 printer, one of the world’s largest metal Additive Manufacturing platforms.

“The dream of winged spacecraft has always hinged on propulsion systems that breathe air at hypersonic speeds before transitioning to rocket mode,” said Lin Kayser, Co-Founder of LEAP 71. “By combining Computational Engineering with large-scale metal Additive Manufacturing, we now have a shot at overcoming some of the most fundamental barriers to realizing that vision.”

“At hypersonic speeds, incoming air can reach several thousand kelvins due to stagnation effects,” said Josefine Lissner, Managing Director of LEAP 71 and Principal Architect of Noyron. “To manage these extreme temperatures, we implemented a fractal folding algorithm in Noyron to maximize the available surface area without compromising aerodynamic flow. The intertwined structure separates the superheated air from the liquid-hydrogen coolant, enabling rapid thermal exchange in a compact, manufacturable form.”

Farsoon Technologies and LEAP 71 worked closely to fine-tune Noyron’s manufacturing output, successfully producing one of the tallest metal powder-bed fusion parts ever built.

“This collaboration demonstrates how the convergence of large-format metal additive manufacturing and AI-driven design can redefine the limits of aerospace engineering,” said Oliver Li, General Manager, Farsoon Europe GmbH. “Farsoon’s open, industrial-scale LPBF systems empower partners like LEAP 71 to transform digital intelligence into tangible high-performance components — proving that innovation and collaboration are the true engines driving the next generation of space technology.”

The two companies aim to reignite the discussion about reusable spacecraft and broaden the focus toward alternatives to today’s vertical takeoff and landing paradigm.

The finished precooler will be exhibited at Formnext 2025 in Frankfurt, at the Farsoon booth (Hall 11.0, Booth E11).

About Farsoon Technologies

Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal Laser Powder Bed Fusion (LPBF) systems. With the established multi-disciplinary team in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. Farsoon was founded with the vision of creating an innovation-based company that brings truly open industrial additive systems and value-added solutions to the global market. For more information, visit https://www.farsoon-gl.com

About LEAP 71

LEAP 71 was founded on the vision that radically accelerating real-world engineering is essential to shaping the future of humankind. Strategically based in Dubai, UAE, the company works with customers worldwide to design advanced machinery across aerospace, electric mobility, robotics, and thermal systems.

A pioneer in the emerging field of Computational Engineering, LEAP 71 designs physical objects autonomously — without manual modeling or human input. At its core is Noyron, a Large Computational Engineering Model that encodes logic, physics, production methodologies, and real-world feedback into a coherent, deterministic system. It has been called “the first AI that builds machines.”

Noyron generates functional designs in seconds or minutes, optimized for modern manufacturing technologies such as industrial 3D printing.

A key focus for the company is extending humanity’s footprint in space. LEAP 71 is developing a spectrum of reference designs for space propulsion systems that serve as the DNA for customer-specific engines. Frequent physical testing and validation continuously enrich Noyron’s models.

LEAP 71 was founded in 2023 by aerospace engineer Josefine Lissner and serial entrepreneur Lin Kayser.

Visit the LEAP 71 website for more information.