Hip Trabecular Implant

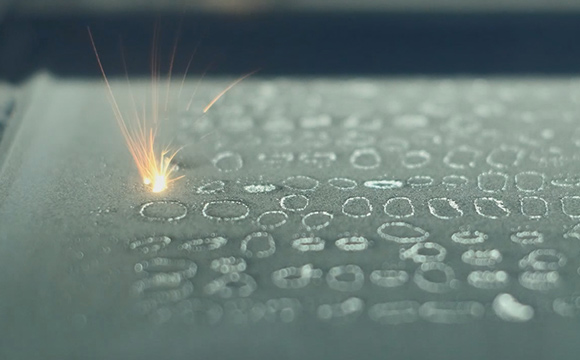

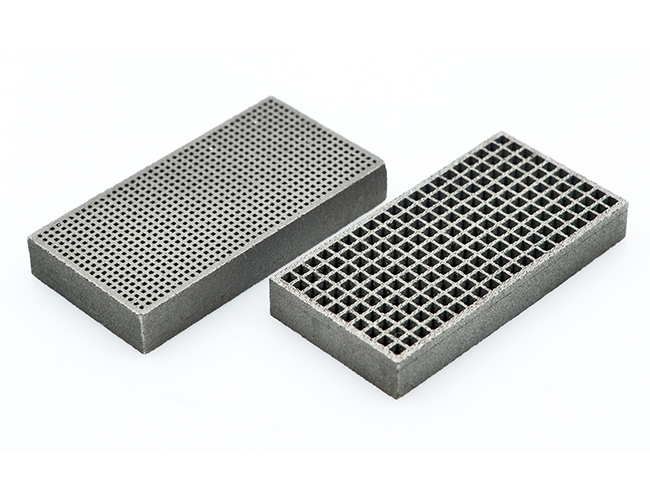

Machine: FS121M

Material: Tantalum

High relative density of the part: 99.3%

This Implant is a customized device for repairing the trabecular bone at the hip joint. The standard implant device are regular solid-surface structured with low fatigue tolerance; which is not suited for patient’s condition. Thanks to Farsoon metal additive technology, surgeons are able to fully customize porous structure that tailored-made for diagnosis, which features a design porosity of 68-75% and aperture diameter 250-500um. The implant is produced with optimal performance, high size accuracy to ensure the best fit for application and fast recovery.

VIEW HEALTHCARE INDUSTY