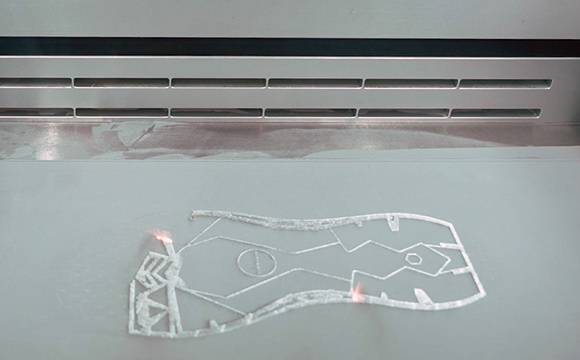

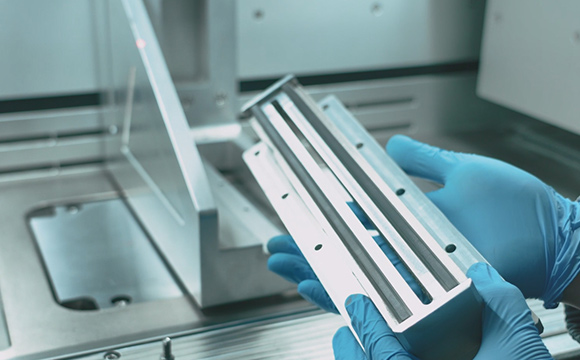

Shoe Mold

Machine: FS200M-2

Material: Aluminum

Size: 332 x 138 x 66 (H) mm each

Build Time: 17 Hours

Targeting a series of challenges in traditional shoe sole manufacturing including frequent design updates, low volume customization, and complexity of the pattern, many shoe manufacturers has adopted 3D Printing technology for direct production of end-use shoe sole molds. Rapidly produced on Farsoon’s FS200M dual laser system in only 17 hours, the shoe sole mold has achieved significantly shorter lead time compared to traditional manufacturing. The as-printed part is able to achieve a high surface quality which only need minimum post-processing such as bead blasting before used for injection molding.

VIEW MOLDS & TOOLING