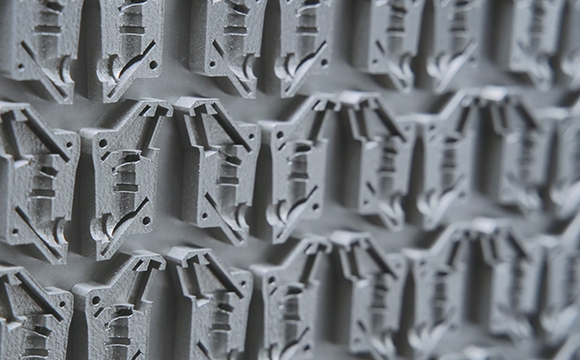

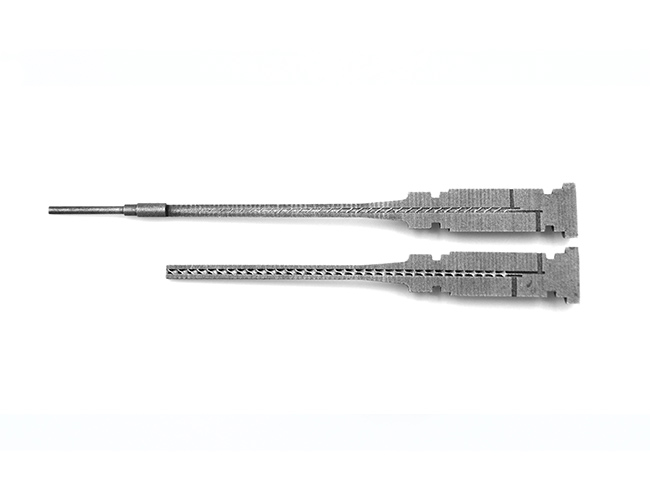

Pen Mold Insert

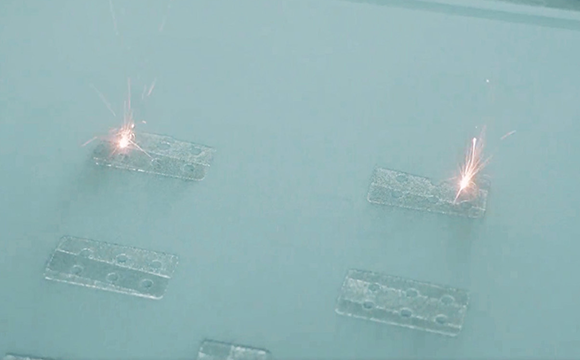

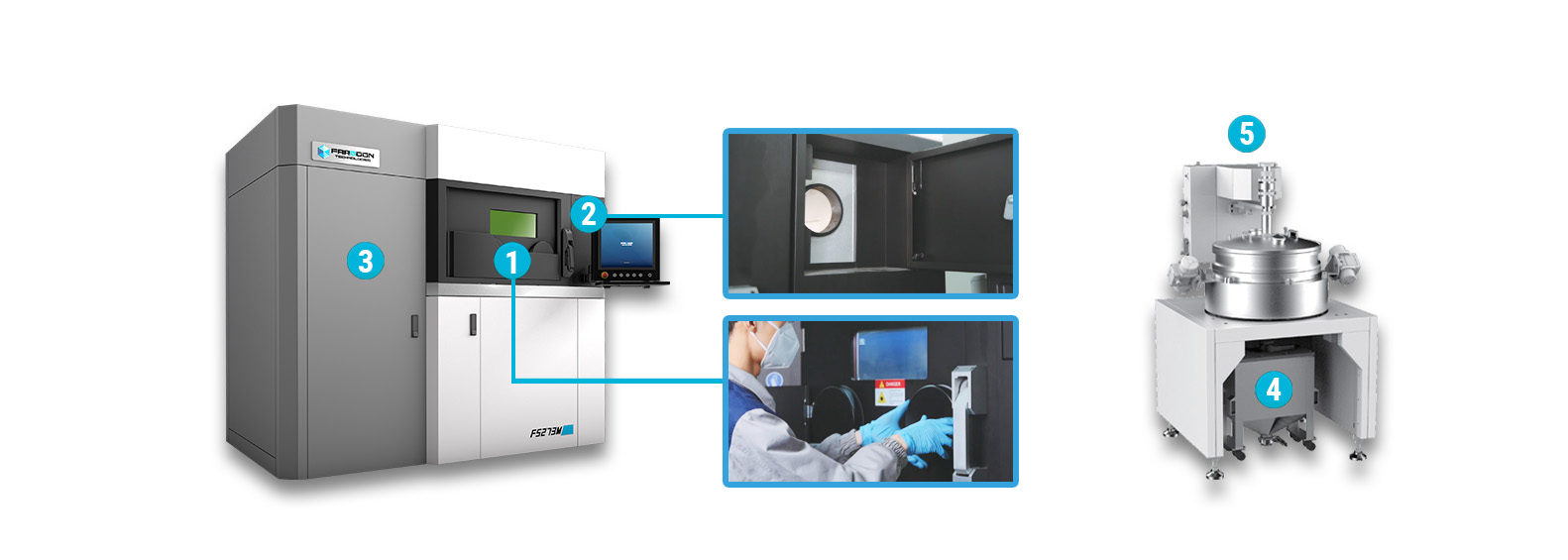

Machine: FS273M

Material: Stainless Steel 316L

Reduce operation temperature by: 5℃

Increased waterflow speed by: 43%

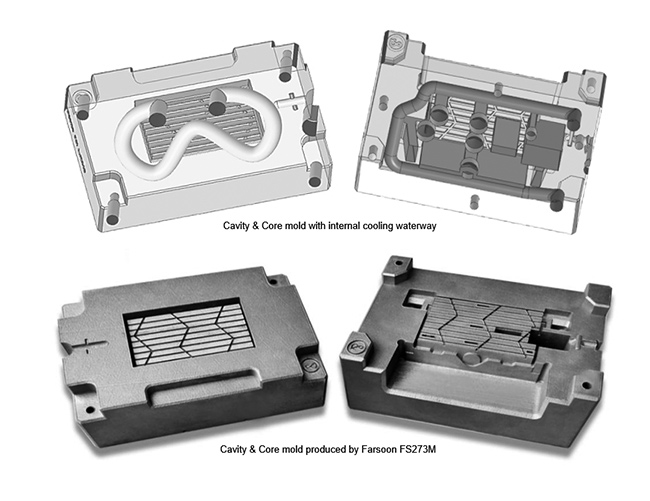

Featured with a narrow shape and complex internal cooling channels, the traditional manufacturing process of this pen mold insert is extremely challenging – often result in unevenness of the wall thickness, demolition and leakage. Thanks to Farsoon metal 3D printing, the engineers are able to create a double spiral structure conformal cooling channel. It increases the surface of the waterway to reduce each cycle time of cooling operation by 30%; and boosting an improved cooling effects and optimal final product quality.

VIEW MOLDS & TOOLING