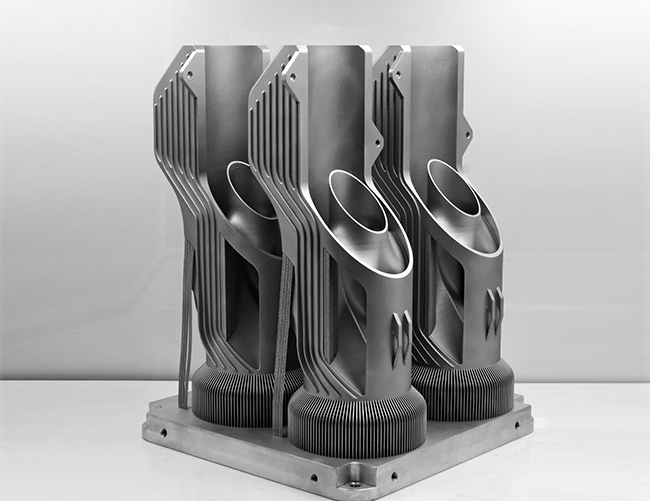

AUV Heat Exchanger Component

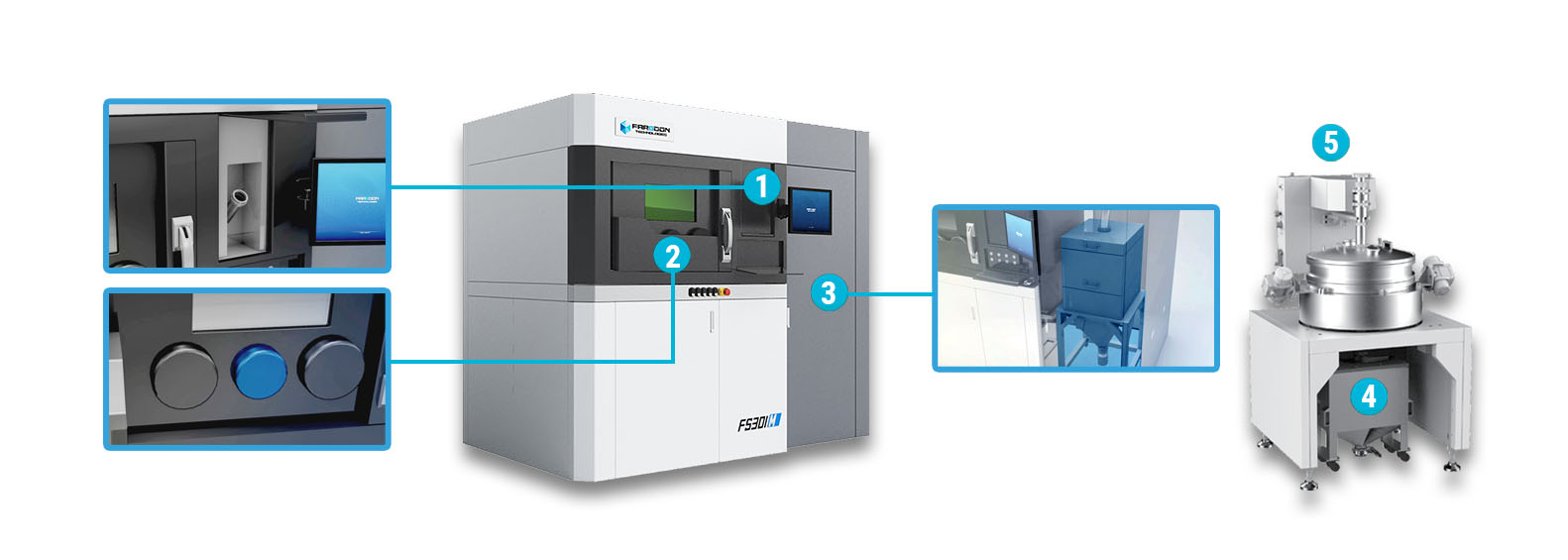

Machine: FS301M-2

Material: Aluminum

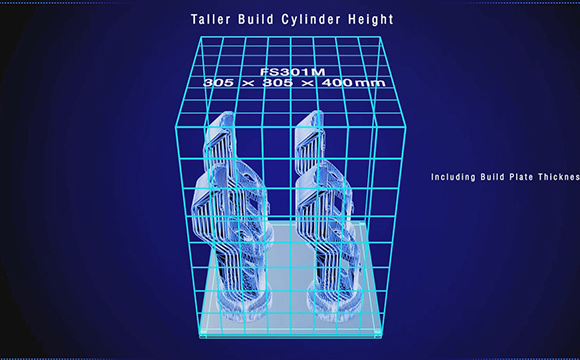

Size: 158 x 136 x 360 (H) mm each

Layer thickness: 0.05 mm

Build Time: 96 Hours

Thanks to the advanced Farsoon metal additive manufacturing, engineers are able to explore brand new design of this heat exchanger component with structural integration, light-weighting and mechanical strength. With this innovative design, the engineers are able to achieve total build time of 96 hours with 0.05mm layer thickness. The as-printed part features excellent surface quality that will only require easy post-processing, like heat-treatment, wire-cutting and sand blasting.

VIEW LIFESTYLE INDUSTRY