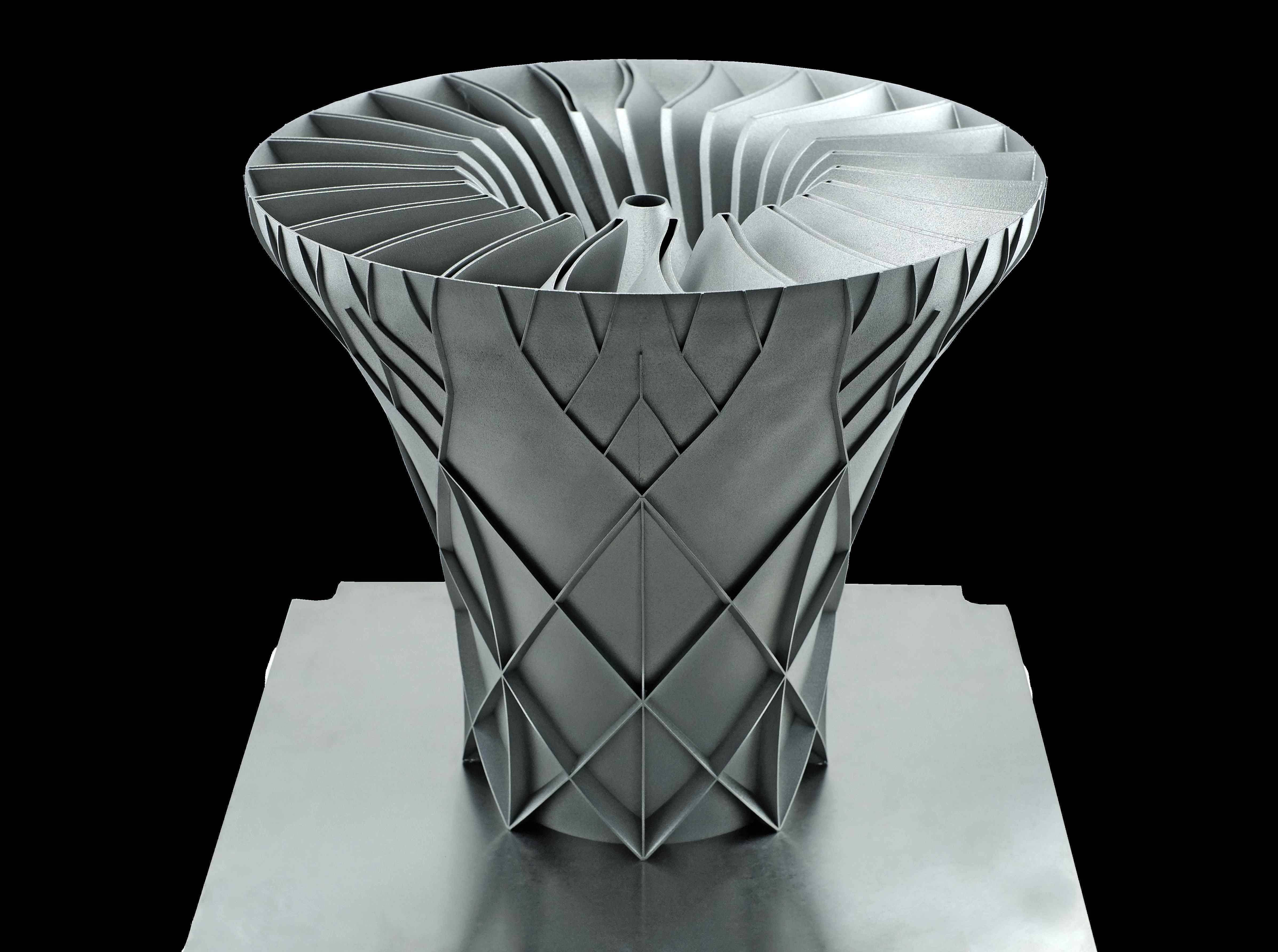

In-line Tube & Shell Heat Exchanger

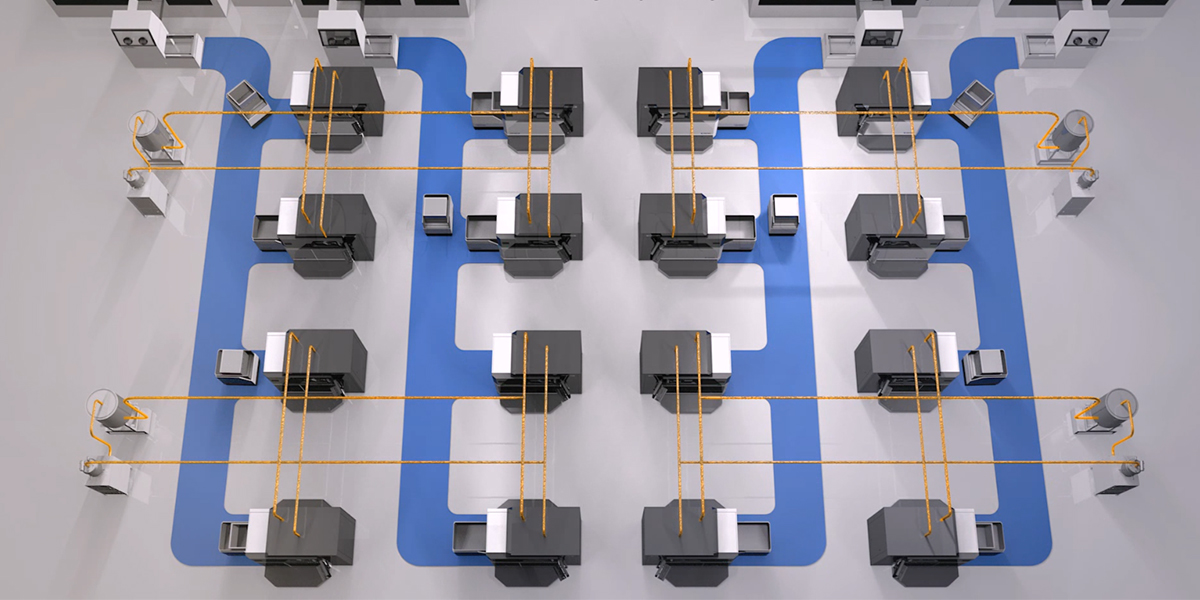

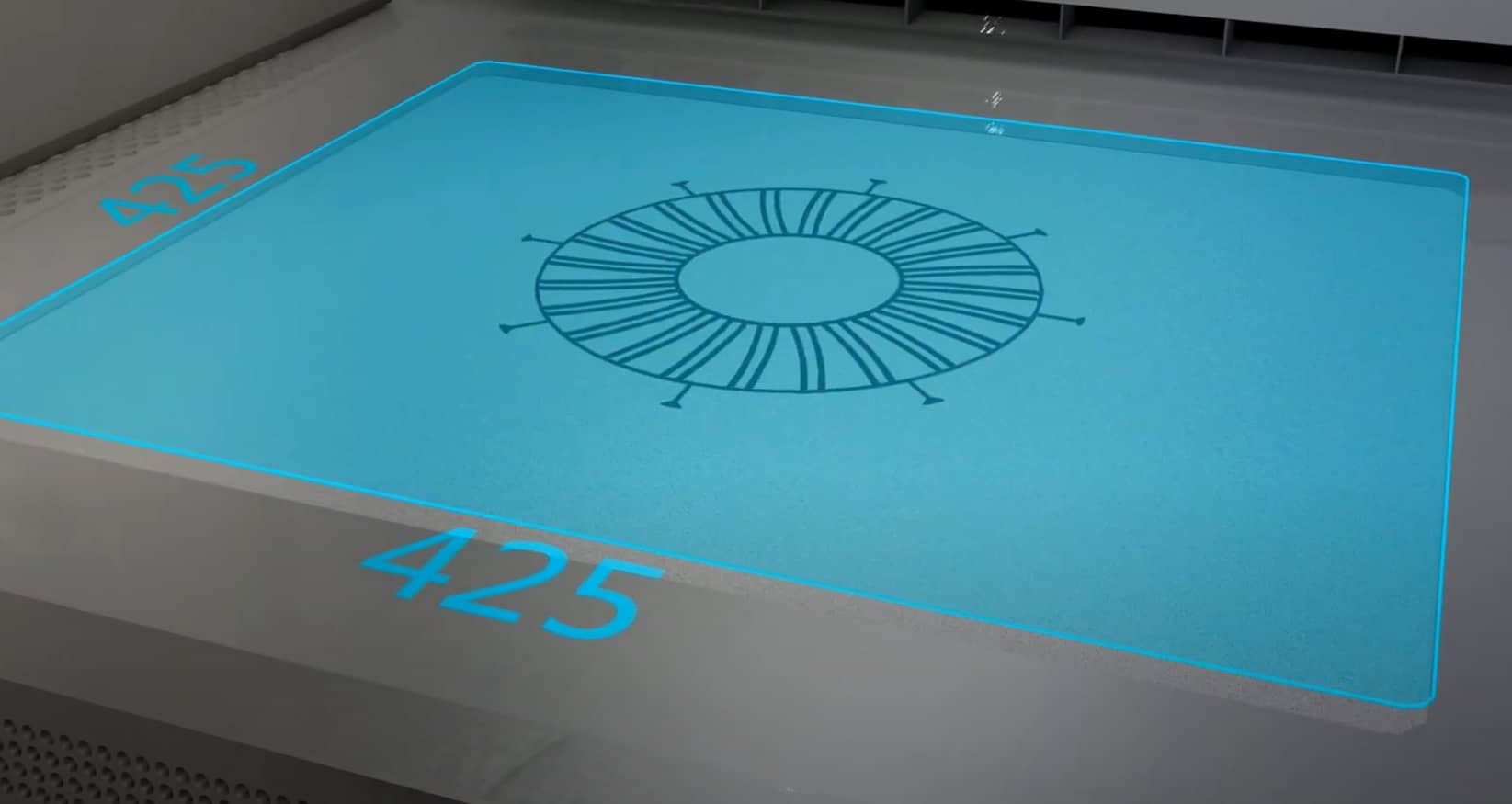

Machine: FS422M-4

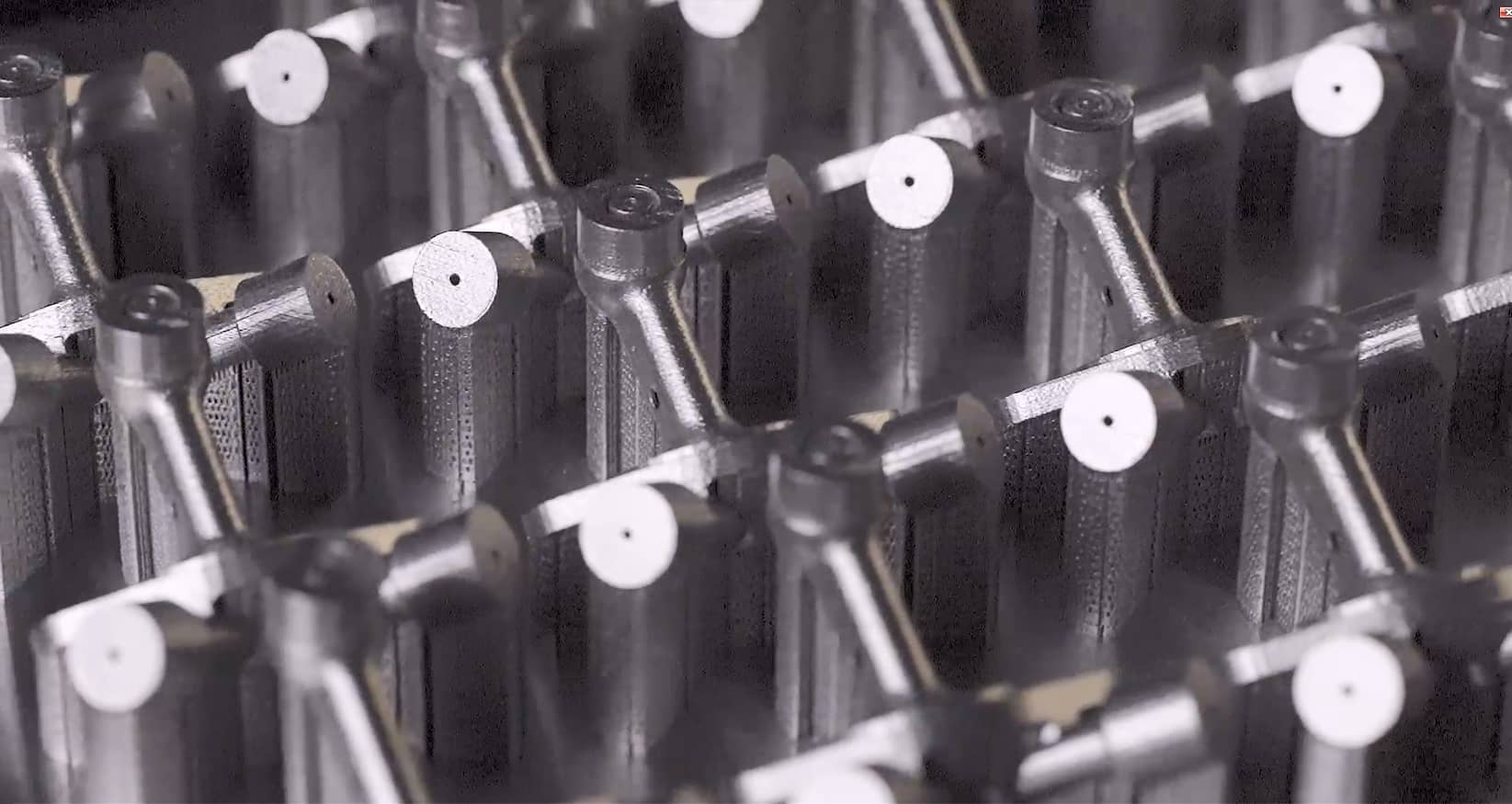

Material: Aluminum

Size: 412 x 412 x 380 (H) mm

This in-line tube and shell heat exchanger is purpose-built for the industrial petroleum industry. Rapid heating and cooling crude oil and its many byproducts during the refinement process is critically important to safety and cost. This integrated heat sink component allows for in-line cooling at a fraction of the cost of expensive, space-consuming traditional equipment. Fluid cavity separation allows for cooling or heating of the petroleum with no contact between coolant and production fluid.

VIEW AEROSPACE INDUSTRY