With 24.72 million people in China living with limb disabilities, the demand for high-performance, accessible prosthetics has never been greater. Handson Bionic Robotics answered this call—and in 2024, their Farsoon PBF-engineered prosthetic hand clinched gold at CYBATHLON, the world’s premier assistive technology championship.

Figure 1: Handson team celebrates victory at Cybathlon 2024. Image courtesy: Handson

Handson Bionics, in collaboration with Southeast University, claimed gold in the Powered Arm Prosthetics Race at CYBATHLON 2024 — the Olympics of assistive tech. Their winning bionic hand owed its agility and reliability to a hidden engine: Farsoon’s industrial-grade 403P polymer Powder Bed Fusion (PBF) technology.

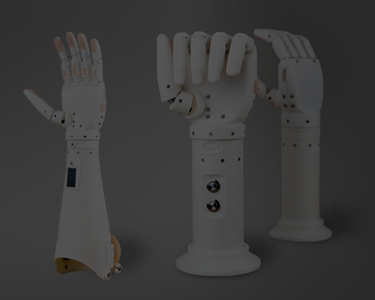

Figure 2: Bionic arms, 3D printed on Farsoon polymer system. Image courtesy: Handson

Engineering Speed: From Weeks to Hours

Traditional prototyping slowed Handson’s progress, requiring weeks to machine complex bionic joints. By adopting Farsoon’s industrial polymer Powder Bed Fusion (PBF) technology through manufacturing partner Wenext, Handson shattered these barriers:

• Produce complex bionic joints in 24 hours

• Achieve functional testing readiness in just 72 hours

• Eliminate costly tooling and machining for small-batch validation

This acceleration slashed R&D costs by over 80% and liberated engineers to focus on performance—not production delays.

Beyond Speed: The Customization Revolution

Farsoon’s technology enabled more than rapid iteration; it is unlocking and using laser-sintered high-performance polymers like PA12 and TPU, Handson could:

• Customize socket interfaces and joint geometries for individual users

• Optimize weight distribution and biomechanical efficiency

• Achieve industrial-grade durability

• Simplify maintenance through modular, interlocking designs

This flexibility proved critical in creating prosthetics that users could afford and adapt to — core to Handson’s mission.

Figure 3: A fleet of Farsoon 403P series at Wenext AM Center. Image courtesy: Wenext

Scaling Impact with Wenext’s AM Ecosystem

Wenext’s dedicated Farsoon SLS production hub—equipped with 20 403P Polymer Series systems—translated Handson’s designs into reality at scale.

• High-Volume Capacity: 3M+ annual parts for 200k+ clients

• End-to-End Workflow: Integrated post-processing, QA, and fulfillment

• Batch-to-Batch Consistency: Medical-grade repeatability

Handson’s CYBATHLON victory demonstrates how Farsoon PBF technology accelerate innovation and rapid manufacturing in bionics industry. Begin your additive manufacturing journey today elevating speed, cost-control and ROI by contacting Farsoon: globalinfo@farsoon.com.