In global shoe mold manufacturing, key industry challenges include the need for increased production efficiency, higher precision, and more adaptable supply chains. Farsoon Technologies has addressed these demands through the industrial application of its metal additive manufacturing (AM) systems. This technical overview details the implementation and performance of over 100 installed Farsoon metal AM systems dedicated to shoe mold production.

Global Deployment and Application

Farsoon’s metal AM systems are deployed across major shoe manufacturing regions, including the United States, Southeast Asia, South Korea, and China. This widespread adoption is supported by localized technical service networks in areas such as Indonesia and Vietnam.

Specific industrial applications include:

• A major U.S. sportswear brand utilizes Farsoon systems for the production and iterative development of functional shoe components.

• In Indonesia, a high-volume mold manufacturer operates multiple Farsoon FS350M systems, transitioning from dual-laser to quad-laser configurations to fulfill production orders.

• Manufacturing entities in Vietnam have scheduled the installation of more than 10 additional systems for 2025.

• Several manufacturers in South Korea have integrated the technology to address objectives related to carbon reduction and process automation.

• A large-scale production facility in China has integrated over 50 Farsoon systems into its 24/7 manufacturing operations.

Cumulative output from these installations has contributed to the manufacturing of more than one billion pairs of finished shoes.

System Specifications and Technical Performance

The Farsoon FS350M system, featuring a build volume of 425 × 350 × 400 mm, is designed to accommodate approximately 99% of standard shoe mold sizes. Its multi-laser configuration is engineered for high throughput, capable of producing a single large mold or multiple smaller molds in a single build cycle.

Key technical features contributing to production stability and part quality include:

1. Optimized Optical System: The laser configuration ensures consistent power distribution and spot size across the entire build platform, which is critical for batch-to-batch repeatability.

2. Controlled Airflow Management: A multi-layer airflow system, combined with intelligent printing strategies, minimizes turbulence. This results in improved surface uniformity and reduced particle contamination on optical components, lowering maintenance requirements.

Process and Software Capabilities

Farsoon’s proprietary software suite includes tools developed specifically for the automation of shoe mold design:

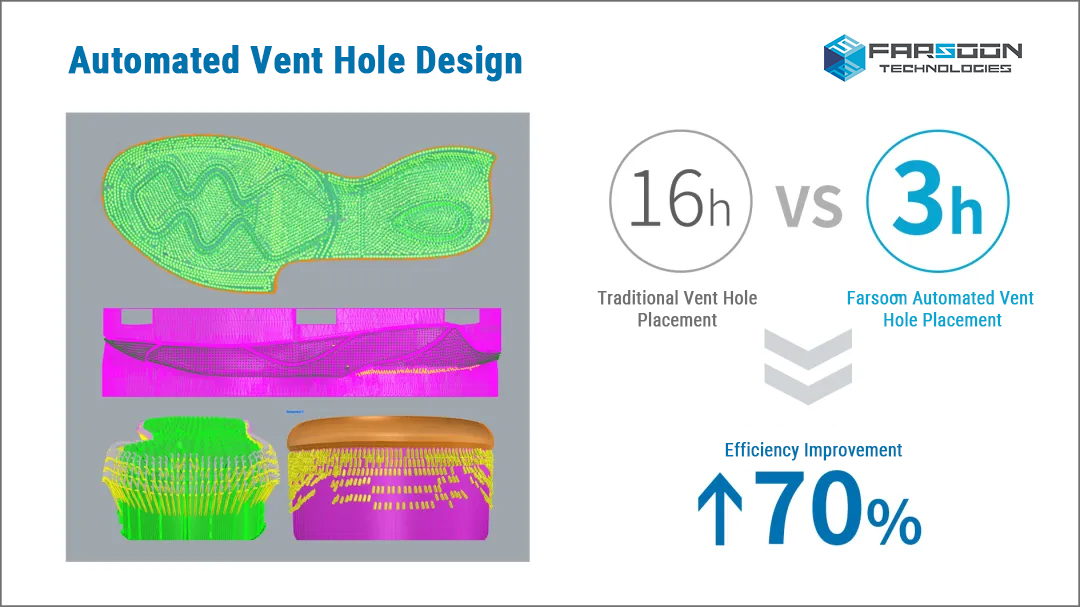

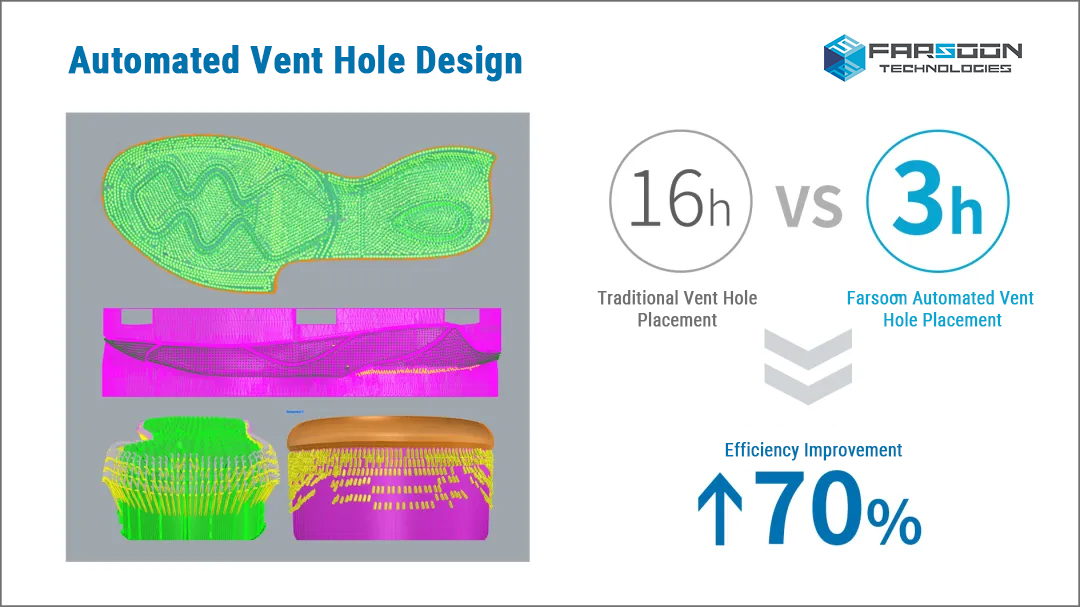

• Automated Vent Hole Placement: The software algorithm calculates optimal vent hole locations based on the 3D topography of the mold, eliminating manual design work.

• One-Click Venting Generation: For complex molds, such as those for “popcorn” soles, this function reduces the design time from approximately 16 hours to 3 hours, streamlining the pre-production workflow.

Process Development for Mold-Specific Challenges

Continuous process parameter development has yielded solutions for several common technical challenges in metal AM for shoe molds:

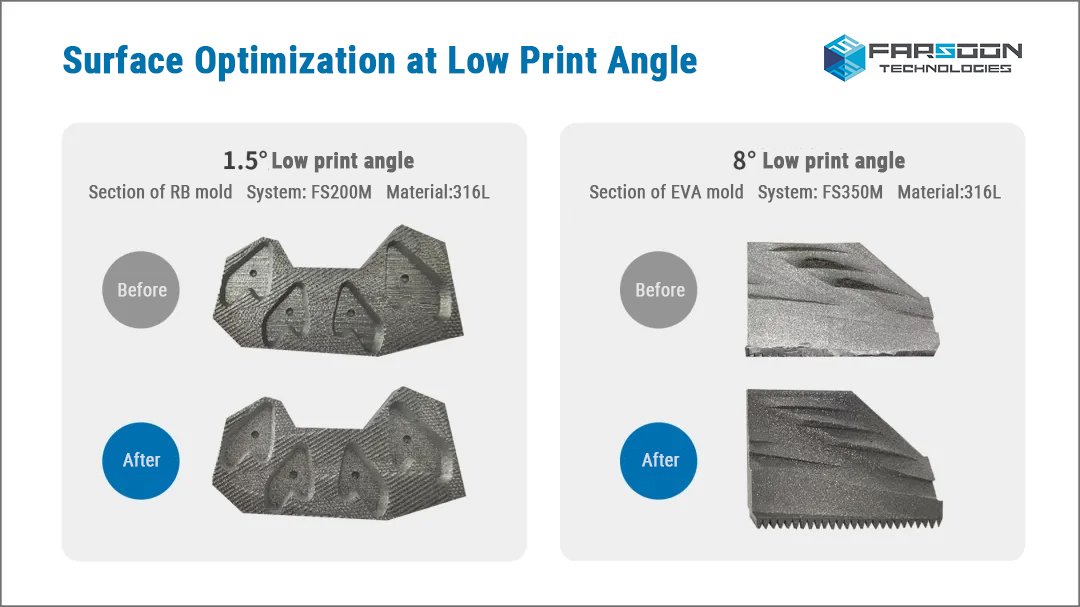

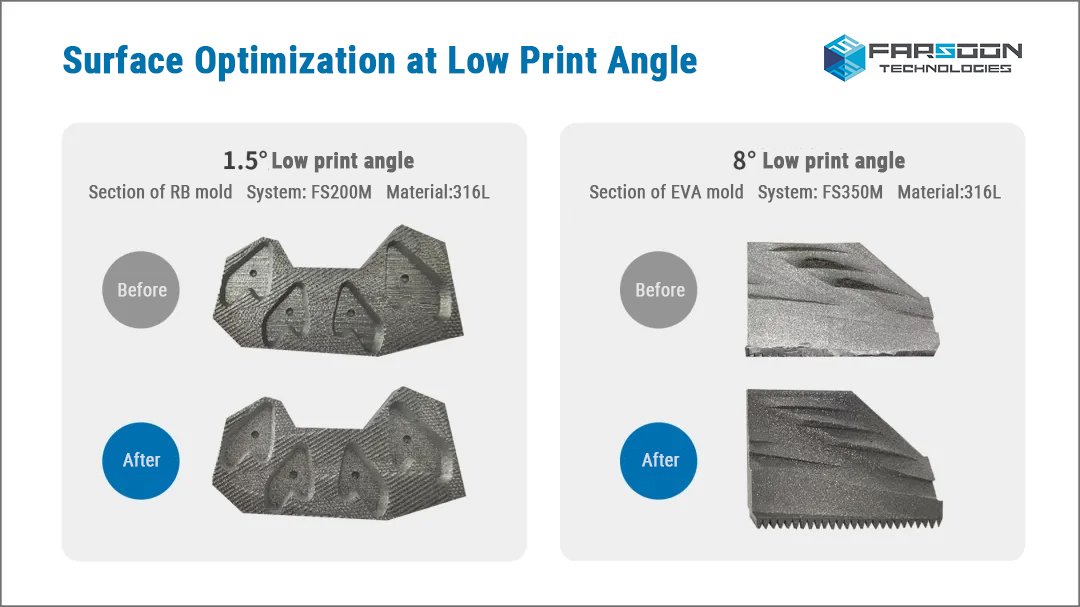

• Low-Angle Printing: Parameter sets have been optimized to successfully manufacture EVA shoe molds with angles as low as 8°, overcoming typical limitations of 45°. This reduces surface roughness and eliminates the need for manual support removal. For RB molds, parameters have been refined to produce a 1.5° angle without stair-stepping artifacts, minimizing post-processing.

• Fine Feature Reproduction: For aluminum IP molds, a controlled melt pool process enables the accurate reproduction of intricate details, including patterns with depths of 0.13 mm and widths of 0.1 mm, ensuring high fidelity to the original design data.

Conclusion

Farsoon Technologies’ metal AM systems have been implemented in high-volume production environments for shoe mold manufacturing. The technology demonstrates capabilities in increasing production throughput, ensuring part consistency, and enabling complex geometries that are difficult to achieve with conventional methods. Ongoing development focuses on further advancing process parameters and expanding material options to meet evolving industry requirements.