A pioneer and leader in the Chinese small appliances market, Joyoung invented the world’s first fully automatic household soybean milk maker in 1994. Driven by its core DNA of sustainability and innovation, Joyoung has expanded from kitchen appliances to living room and whole-house solutions over its 30-year history. The company consistently ranks #1 in multiple product categories through continuous technological advancement.

Facing intensified market competition, Joyoung needed to drastically compress R&D cycles while maintaining rigorous validation standards for new products (functional testing, market trials, 3C certification).

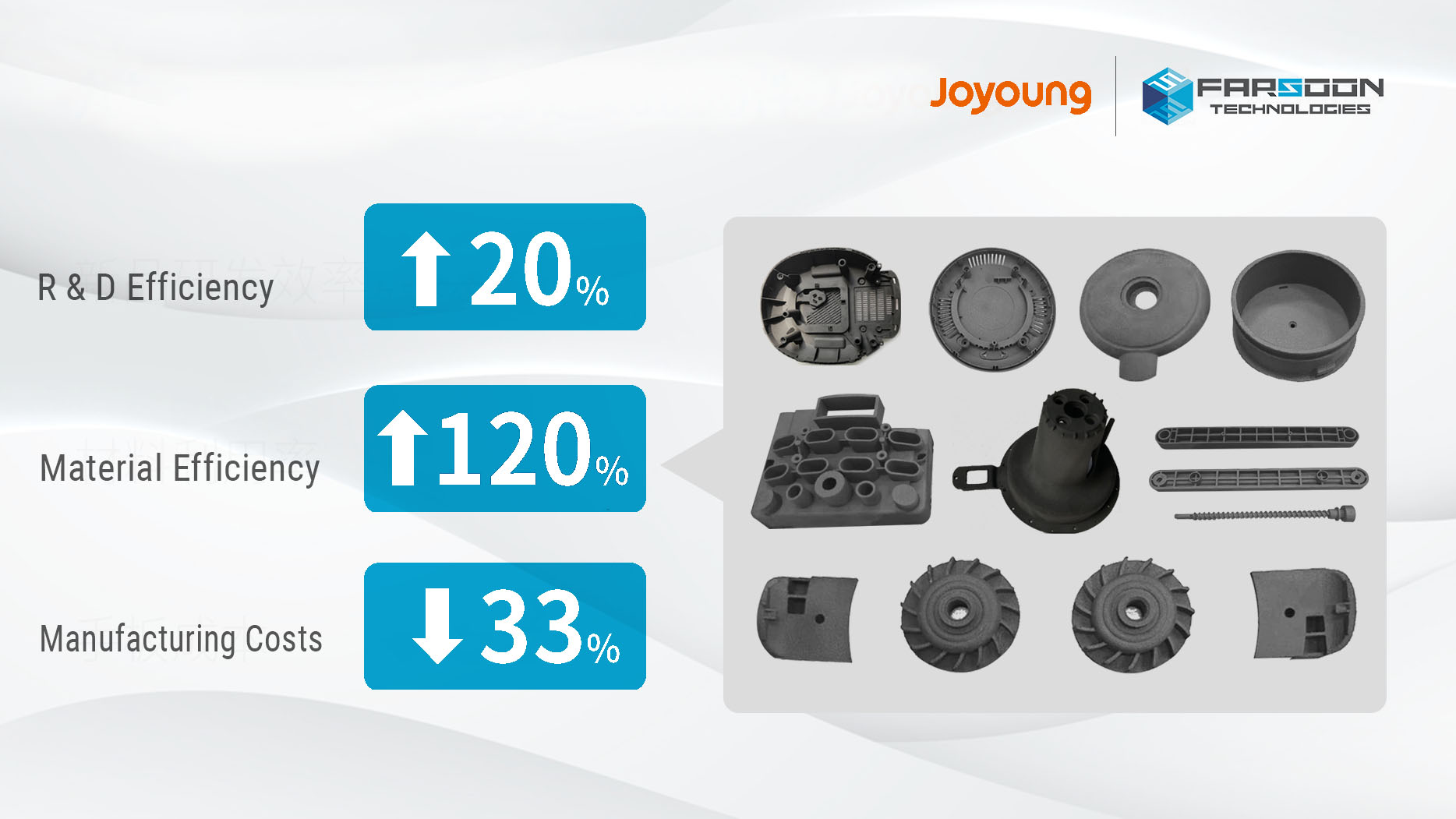

Figure 1: Examples of key appliance components by Farsoon Flight® Technology. Image courtesy by Joyoung.

In 2024, Joyoung integrated Farsoon’s Flight® 403P high-temperature polymer PBF system into its core development workflow. Key operational success including:

• Serial Production Scale: 10,000+ functional prototypes annually (>1 ton material processed)

• Lead Time Reduction: Prototyping cycles slashed from 3-5 days (traditional CNC) to 1-2 days (60% faster)

• R&D Efficiency: Overall development acceleration of 20%

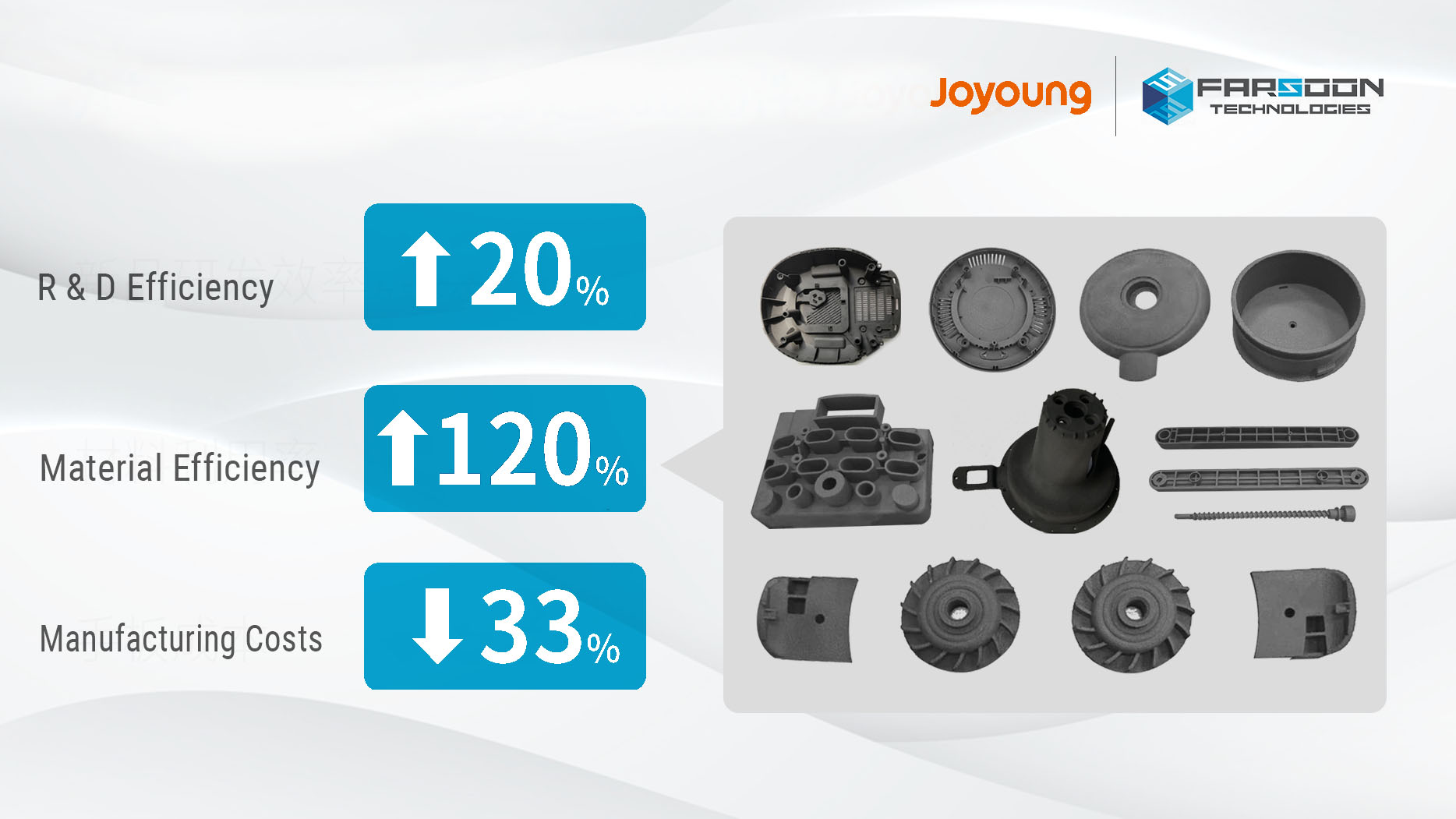

Figure 2: Validated competitive advantages with Farsoon Flight® Technology. Image courtesy by Joyoung.

Critically, Farsoon’s Flight® PBF technology delivers quantifiable, industrial-grade contributions across Joyoung’s serial production workflow—demonstrating data-supported impact in four strategic pillars: productivity amplification, cost efficiency optimization, functional part performance, and IP confidentiality. We now examine these validated competitive advantages:

• Speed & Enhanced Engineering:

Flight® enables rapid design iteration and small-batch validation. Example: Full prototype sets for complex appliances (Zero-Coating Rice Cookers, Blenders) printed within 48 hours, enabling immediate assembly checks and functional tests (mechanical strength, thermal resistance @ 145°C). This agility built critical competitive barriers for product launches.

• Cost Efficiency & Sustainability:

Prototyping costs reduced by 33% – from ¥15M (traditional methods) to ¥10M annually (combining Flight® SLS and SLA). Flight®’s closed-loop powder recycling achieves >90% material utilization, aligning with sustainable manufacturing.

• Performance-Driven Materials:

Industrial-grade polymers (e.g., FS3201PA-F nylon) meet stringent requirements:

o High Temp Resistance: Withstands 145°C for steam/liquid validation (soybean milk extraction, rice cooking).

o Mechanical Integrity: Glass-fiber reinforced options ensure structural robustness.

o Precision: ±0.1mm accuracy enables micro-apertures and intricate geometries.

• IP Security:

End-to-end digital workflow (CAD-to-part) establishes a secure, closed-loop production environment, eliminating prototype leakage risks during critical pre-launch phases.

“Flight® technology reshapes small appliance R&D,” states Manager Wu Chuang of Joyoung’s Innovation Workshop. “It’s trifecta of speed, performance, and cost control fuels faster, bolder innovation. We anticipate deeper integration driving further breakthroughs.”

This collaboration demonstrates polymer PBF’s maturity for industrialized prototyping. Joyoung’s 10,000-part/year operation sets a benchmark for leveraging AM as a strategic, high-volume production tool accelerating time-to-market in competitive consumer goods sectors. Explore more solutions for serial polymer AM production, contact Farsoon: globalinfo@farsoon.com.

About Flight® Technology:

Employing industrial fiber lasers in place of the standard CO₂ lasers found in standard laser sintering systems, Farsoon’s Flight® Technology opens many new possibilities for production-targeted additive manufacturing. An industrial fiber laser can deliver greatly increased power to the powder bed, thus enabling extreme sintering speeds that pushes the SLS productivity to a new level. Due to the more robust and stable nature of a fiber laser system it also provides increased laser longevity as compared to a CO₂ system. In addition, with its increased power and energy absorption characteristics Flight® Technology will be capable of accessing a much different range of process-able materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for AM material and application development. Visit www.farsoon-gl.com for more info on Flight® plastic laser sintering systems.