Background:

Robotics is a multi-disciplinary science involving traditional fields including Mechanical Engineering, Control Systems, Material Science and Information Technology. The latest generation of robotics has even opened to other fields such as Computer Science, Bionics, as well as advanced manufacturing. The RoboMaster Competition provides a unique opportunity for young engineers to test their innovation and gain hands-on experience in the field of robotics. Marking its 6th year competing in this international event and having won 2 championships since 2017, the Robotic Team of South China University of Technology (SCUT) has developed a team of experts in Robotics engineering. With more than 200 participating teams this year, the SCUT team has been seeking brand-new solutions for improved efficiency and quality workflow from design to manufacturing. These young luminaries saw their opportunity with Autodesk and Farsoon Technologies.

Challenge:

There are three main challenges: design iteration, weight reduction, and strength requirements. For each year RoboMaster will announce different requirements, and each team needs to tailor their design accordingly for the final contest in only 8 months. In order to achieve the best performance of the robot, traditionally the design team had to make 4-5 complex “design-build-test” iteration, each cycle including mechanical design, dynamic analysis, structural analysis, assembly, programming, testing, etc.

The object of focus is a stabilizer mount on the robot, a key component which connects the mobile system with the upper projectile system. It is designated to perform complex and rapid movements such as steering, aiming and shooting during the competition, of which the weight reduction of this component has been the key to achieving optimum performance. On the other hand, the robot will experience various extreme conditions including collisions, pellet impact and vibration during the contest. As the keystone in the robot design the stabilizer mount requires extreme mechanical strength in order to avoid any damage on the contest field.

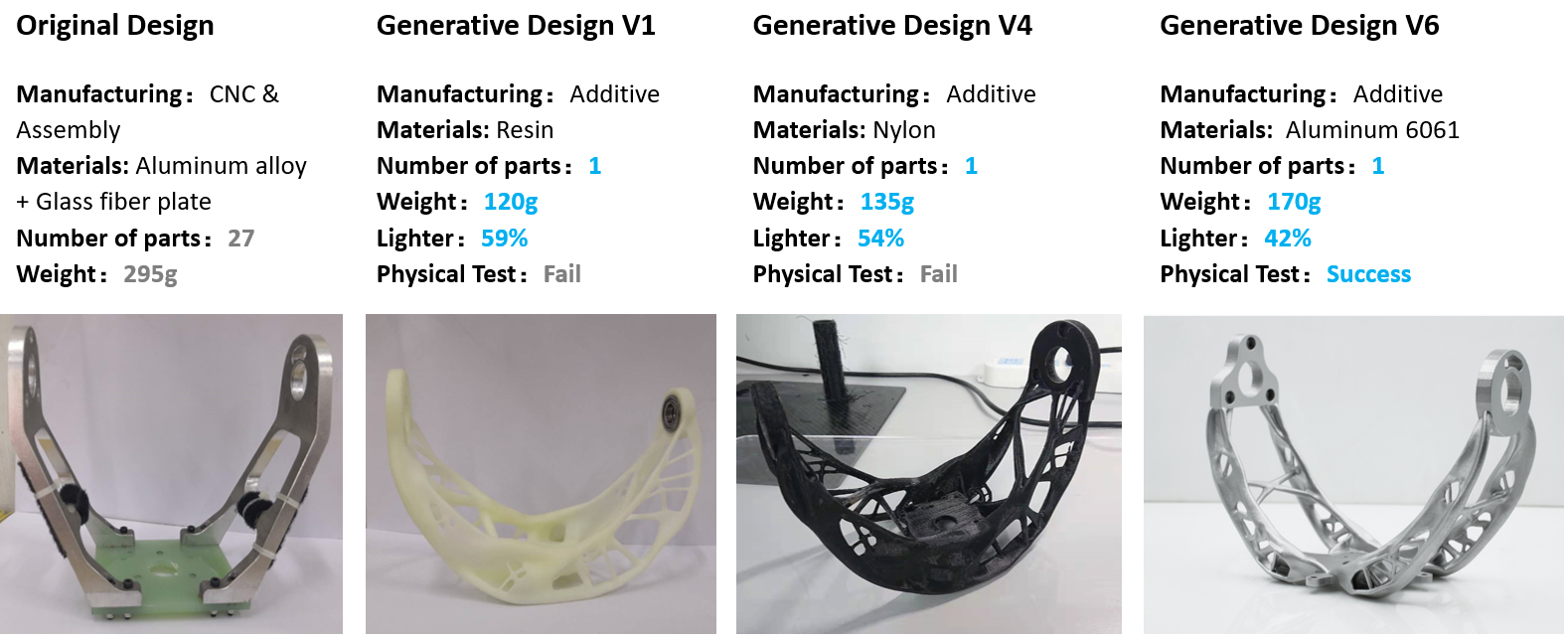

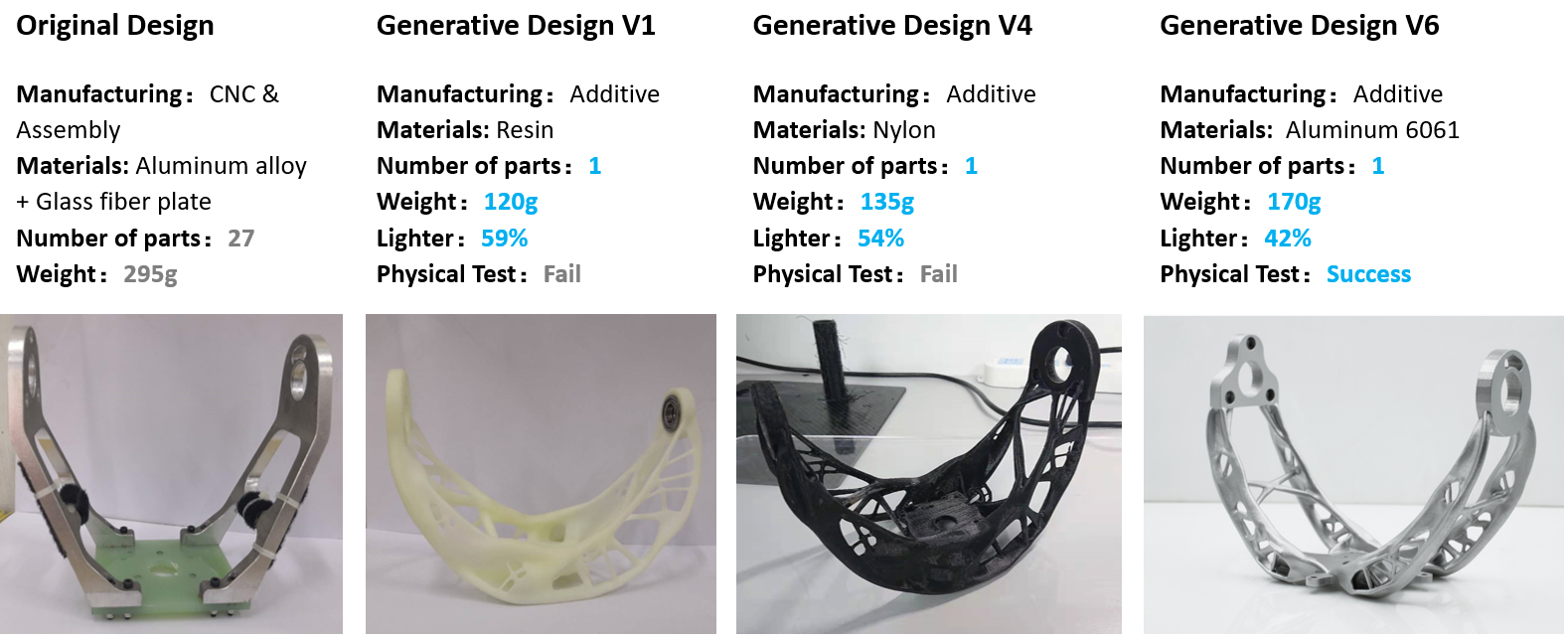

Previously the design of stabilizer mount was limited by the production method, mainly CNC machining with further assembling of up to 27 parts. The weight of these assembled parts could be up to 295 grams, resulting in slower reaction times and movement speeds; in addition, the assembled parts increased the potential for damage during impacts. (Figure 1)

Solution:

At the beginning of 2019, SCUT team began to adopt Autodesk software and Farsoon Metal Additive technology to improve the design and manufacturing process. The additive technology offers unprecedented freedom in flexibility of the geometry of design that suits best for the application.

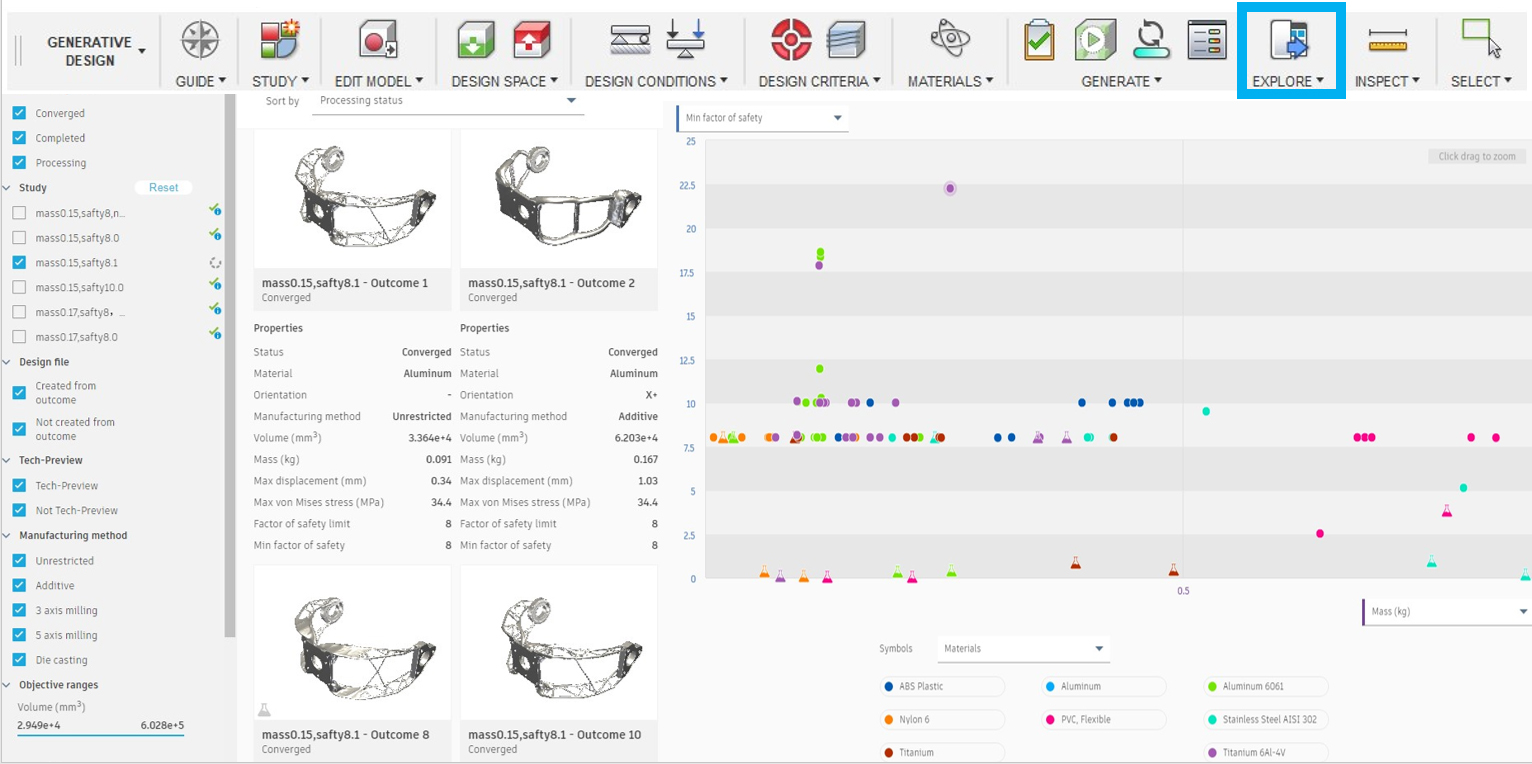

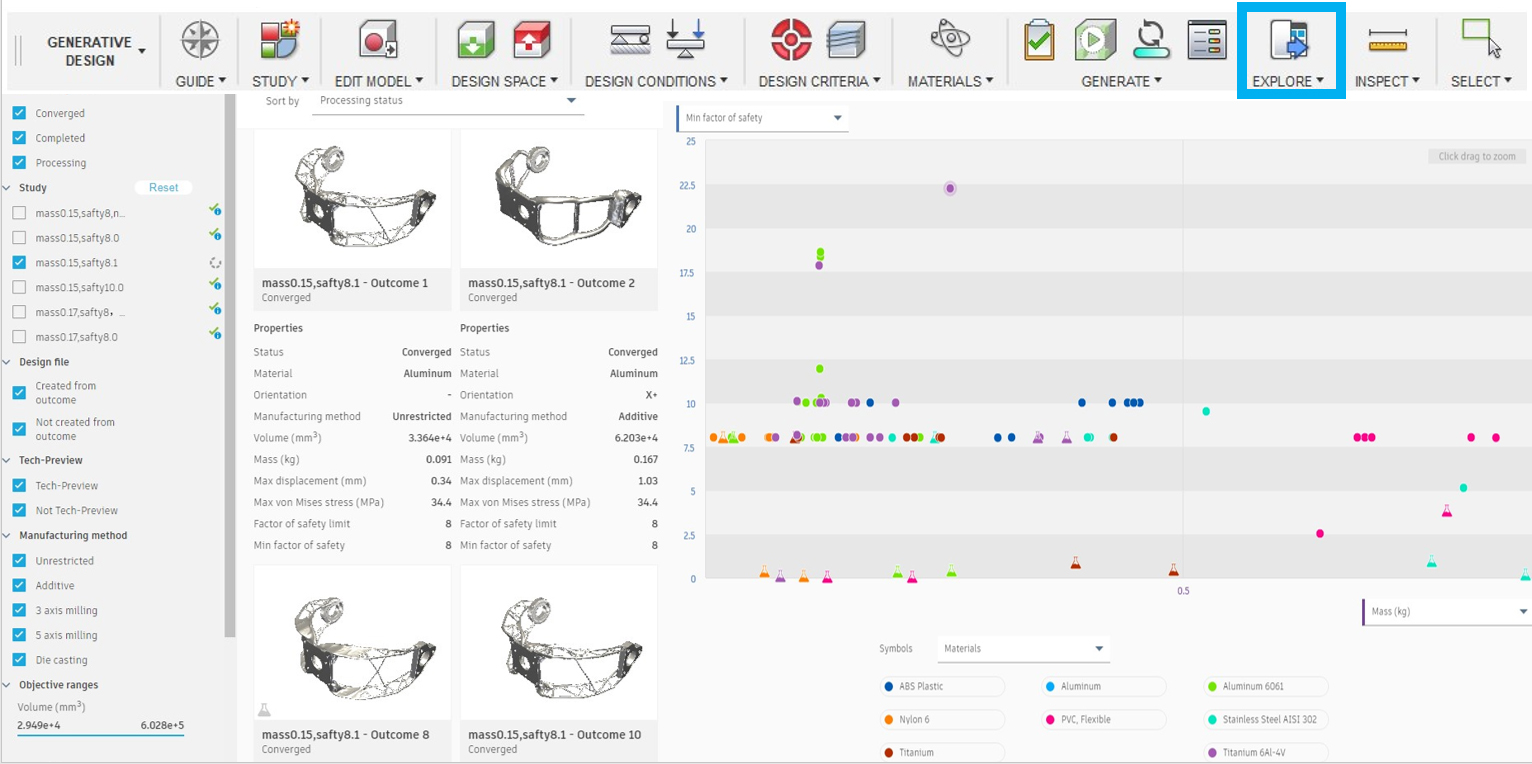

Generative design, a key feature in Autodesk Fusion 360, allows SCUT team to apply design conditions and criteria for the stabilizer mount, generating a variety of designs to meet the requirements. The students are able to apply many kinds of working conditions, such as the extreme impact loads during competition to the part, then define the output options such as desired weight limit (light weight target), engineering materials (including Rasin, Nylon, aluminum), safety factor (up to 8) and potential processing method (CNC, milling, additive), etc., to ensure the best performance of the part during the contest. All the options generated can be further explored and tested by the students, in order to choose the optimal design for final manufacturing (figure 2). They choose 3 designs with different materials and processing methods for assembly and field validation: Rasin (Stereolithography), Nylon 6 (Plastic Laser sintering) and Aluminum (Metal Laser Melting). The Rasin and Nylon 6 parts broke in the field impact, while the AlSi10Mg aluminum stabilizer mount produced by Farsoon FS271M metal laser melting technology stands out with its qualified strength and performance (figure 1).

Figure 1: Original design and generative design by Autodesk Fusion 360

This combination of generative design and additive manufacturing completely overturns the concept of a traditional design process. It creates the optimal design in a very short time without the limitations of traditional processing and materials options.

Figure 2: Autodesk Fusion 360: explore and comparison of the generated options

Results:

The optimized additive manufacturing stabilizer mount achieved a final weight of 170 grams – a 42% weight reduction compared to the original CNC process. The lighter weight means a faster response to signals and improved mobility in the field. At the same time, by combining 27 parts to only 1 single part, it reduces the material waste while enhancing the strength by generatively adding supports, thereby reducing the mass of the robot while ensuring structural integrity.

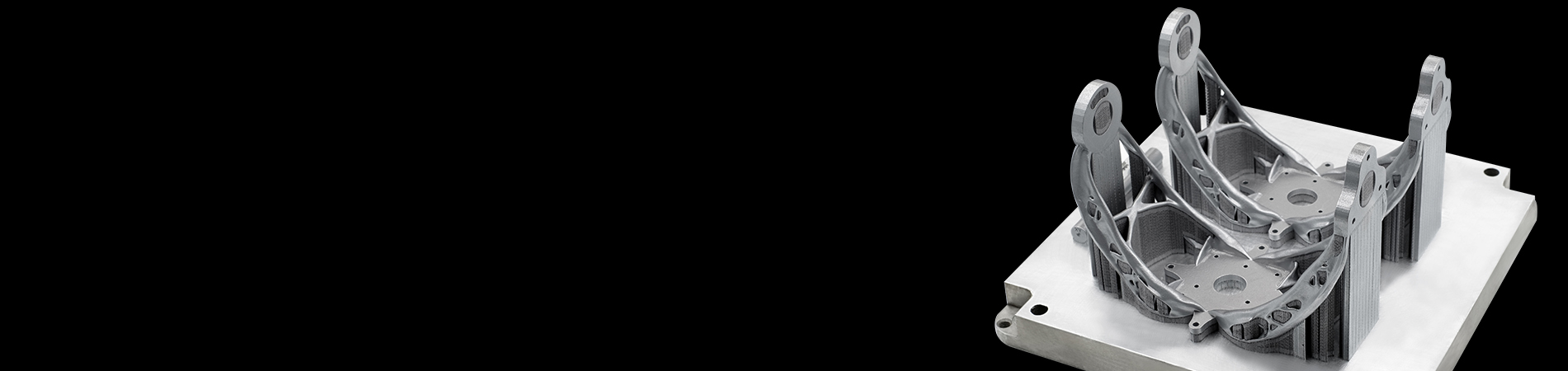

This brand-new workflow also helps accelerate design iteration from the development process to manufacturing. The traditional design by engineer is limited by his own experience, while generative design employs cloud computing to help generate and iterate the optimal result. Compared to traditional manufacturing, additive technology can build 2 sets of stabilizers in only 2 days (figure 3). The whole workflow is simplified with improved efficiency, meanwhile it offers the best solutions for application.

Figure 3: additive produced stabilizer mount on Farsoon FS271M base plate.

Faster design iteration helps the SCUT team to work much more efficiently and reduce the cost of material and manufacturing. This year, SCUT team achieved significant cost reduction to research and development. Take the mechanical team for example, the entire iterative cost was reduced by 80%, which would not have been possible before.

With the help of additive technology, the SCUT team entered the RoboMaster (South-China area) contest on May 23, 2019. The optimized design and improved performance of the stabilizer mount enabled the SCUT team to win the Championship despite intense competition. (figure 4)

Figure 4: SCUT robot with additive manufactured stabilizer during the competition.

“Generative design and additive manufacturing have opened up a new horizon from tradition process,” Said Zhang Dong, Associate Professor of School of Mechanical and Automotive Engineering and Tutor of Robotics Laboratory, “ It helped us find the solution to the key design challenges caused by material limitations and processing methods, which greatly accelerates the design process and reduces production costs. Although we have only achieved 42% weight reduction for one single part, but when you pursuing the perfection, ultimate design of each part is necessary in the future. Taking this new path is exciting yet challenging, but we are confident that only with the technology of innovation, we will make a difference.”

About RoboMaster:

The RoboMaster Program provides unique opportunity for young engineers learn innovation and gain hands-on experience in the field of robotics competition. Hosted by DJI, the world’s leading consumer drone manufacturer, the RoboMaster is on its way to be the most influential robotics competition to date. Each RoboMaster event aims to incorporate the most up-to-date technology in the field of robotics including visual interpolation, hybrid systems, and artificial intelligence. For more information, please visit: https://www.robomaster.com/en-US

About Farsoon:

Farsoon Technologies, founded in 2009 by Dr. Xu Xiaoshu, one of the true pioneers of laser sintering technology with more than 20 years’ experience in the industry, now is a leading machine supplier of industrial Metal Laser Melting and Plastic Laser Sintering systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. With clear vision “Open for Industry”, Farsoon is committed to supporting the industrial production with open systems, materials, parameters and applications. For more information, please visit: www.farsoon.com

About Autodesk:

Autodesk is a leader in 3D design, engineering and entertainment software. Autodesk gives you the power to make anything. Autodesk’s vision is to help people imagine, design, and make a better world. The company was founded in 1982 and is headquartered in the San Francisco Bay Area. Autodesk employs 9,000+ employees worldwide who regularly vote Autodesk one of the best places to work, citing our focus on innovation and collaboration, our inclusive environment, and our emphasis on work/life balance. For more information, please visit: https://www.autodesk.com/

About South China University of Technology Laboratory of Robotics Innovation:

The Laboratory of Robotics Innovation at SCUT was established in November, 2000 at the School of Mechanical and Automotive Engineering. The goal of the Laboratory is to offer an innovative testing space for talented undergraduates to improve their engineering skills via team work. Over the years the team has participated and has received awards in various International competitions, including winning the National Championship of RoboMaster for 2017 and 2018 among 200 teams. The team has submitted 335 national patent applications and 146 authorizations. At the same time, the laboratory has hatched 7 start-up companies and trained more than 500 experts in mechatronics. For more information, please visit: https://www.robomaster.com/zh-CN/resource/pages/906

DOWNLOAD SUCCESS STORY