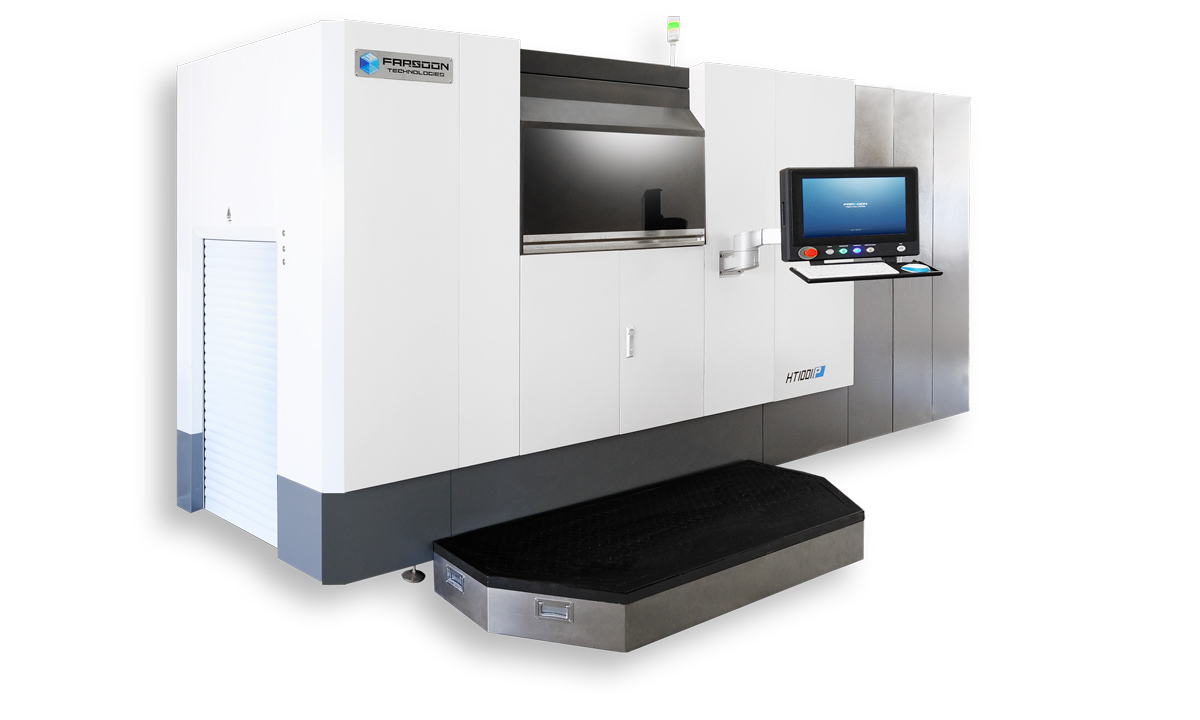

Farsoon Technologies’ HT1001P Polymer Laser Sintering (PLS) System

Frankfurt, Germany and Austin, Texas USA

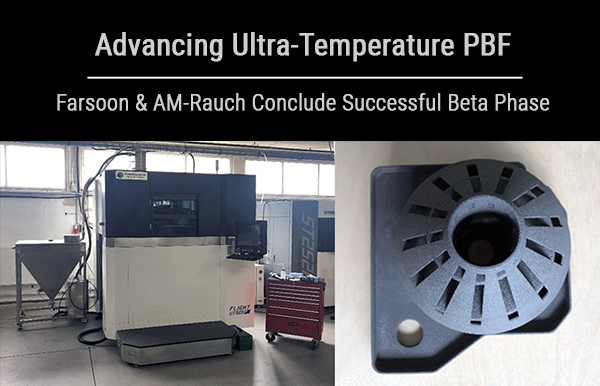

November 12, 2018 – Farsoon Technologies – Americas, located in Round Rock, Texas, is pleased to announce the evaluation program of the new HT1001P large-platform additive manufacturing system. The beta-test assessment of the innovative HT1001P Polymer Laser Sintering (PLS) system, part of the Continuous Additive Manufacturing Solution (CAMS) ecosystem, will take place over the next six months in North America.

The initial scope of this program is the development of an optimized HT1001P system which incorporates highly productive operations in the fabrication of parts for in-use-function to complement global companies additive manufacturing objectives.

The HT1001P enables the fabrication of large parts or multiple quantities of parts (build envelop of 1000 x 500 x 450 mm – 39.37 x 19.68 x 17.71 in) with engineering polymers (plastics), such as polyamides (Nylons), as well as varieties of other specialised materials such as PA6, TPU’s, TPE’s, etc. with the target market being the production of many polymer parts at substantially lower costs.

“We are evaluating Farsoon’s HT1001P 3D printing technology as part of our diverse approach to additive manufacturing,” said John Dulchinos, VP of Digital Manufacturing for Jabil. “The platform’s footprint and performance throughput could add yet another level of productivity to Jabil’s growing portfolio of solutions while its large-format functionality is well suited for meeting our customers’ requirements, especially in the aerospace and transportation industries.”

The HT1001P in operation.

Additive Manufacturing is defined as the production of parts using methods of delivering materials on a layer-by-layer basis to produce a part using computer-aided designed (CAD) software. This technology is ideally suited for many industrial applications across different industries including aerospace, medical devices, automotive, and the production of many consumer products. Additive manufacturing has been flourishing over the last 20 years and is becoming a part of the normal ecosystem for product development and production in the global marketplace. The HT1001P incorporates advancements in workflow management through a conveyor system that manages all steps from pre-heat to the build stage, as well as a cooling module to allow for high-value production capabilities. Speed and quality go hand-in-hand in the HT1001P as it includes a dual 100 watt and a dual digital scanning strategy to combine quality and productivity while overcoming technical hurdles, such as knit/stitch lines through innovative scanning and laser algorithms.

About Farsoon Technologies

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009 in China, is a global comprehensive solution supplier of industrial grade polymer laser sintering and metal laser sintering systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.