May 26th, 2021 – 1st day at TCT Asia – Farsoon Technologies, a leading innovator in industrial laser powder bed fusion (LPBF) technology, is showcasing its Dual-Laser FlightTM Technology on Farsoon’s 403P platform for the first time at TCT Asia 2021 in Shanghai, China (May 26-28, 2021, Hall 7.1, Booth H02 at NECC). In addition, two new Farsoon polymer powders as well as one third party material are being announced for FlightTM Technology providing an expanded material portfolio.

Farsoon’s Dual-laser FlightTM Technology showcasing on 403P platform.

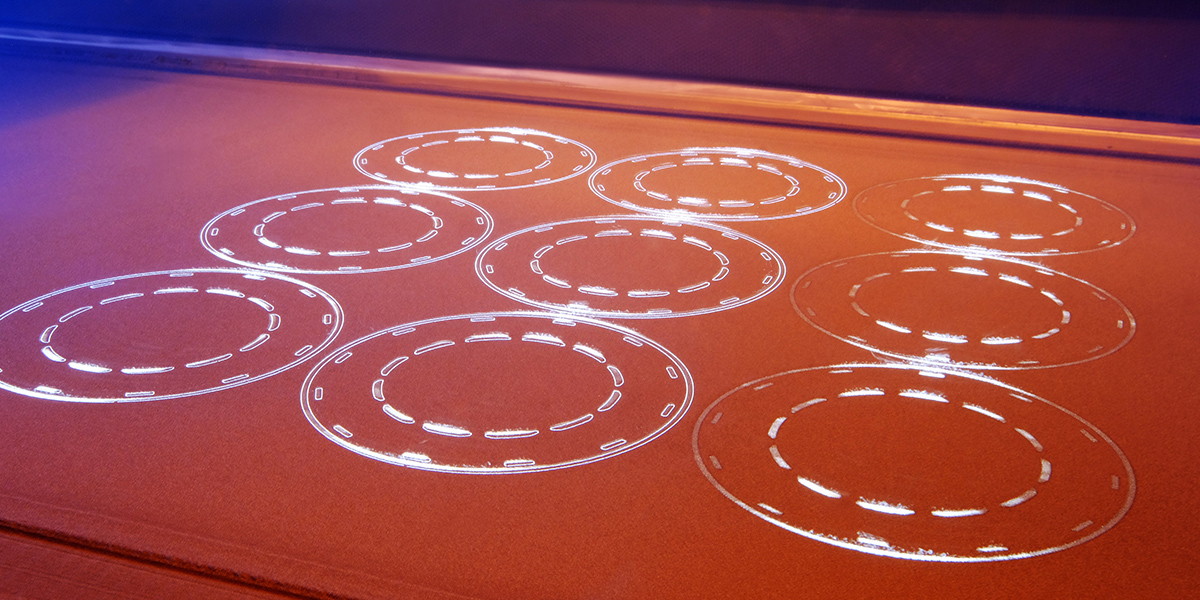

Farsoon is one of the first machine manufacturers to develop production-targeted industrial LPBF solutions using robust Fiber Lasers. The FlightTM Technology unlocks the next level of laser powder bed fusion productivity for industrial-quality parts offering extremely fine details with minimum wall thickness of only 0.3mm. The optimal performance combining extreme sintering speed and high feature resolution has opened up many potential markets and applications for true series production, such as electronic components, robotics, specialized tools & models, battery units, filter modules as well as many consumer products. Also, thanks to the advanced laser powder bed fusion technology, additive agents and other consumables are not required; therefore, enabling lower operational cost and sustainable manufacturing.

Following first introduction of FlightTM Technology and its application on Farsoon’s 403P Series during TCT Asia 2019, Farsoon has been exploring further machine development implementing FlightTM Technology to its high-temperature 252P platform in 2020.

Dual-laser Configuration for Maximized Production Throughput

Developed to address the requirements of industrial-scale series production using LPBF technology, increasing the manufacturing turn-over rate and accelerating the product-to-market cycles, the dual-laser configuration for FlightTM technology takes advantage of two powerful 300-watt Fiber lasers and two dynamic optical systems, creating two ultra-fine laser spots with fast scanning speed of up to 20m/s (66ft/s) for each. The new dual-laser configuration can offer significantly 50-90% higher production volume rate compared to the single laser configuration of FlightTM Technology1, and 3 to 4 times production yield compared to a single CO2 laser machine2. Take its application on Farsoon’s 403P platform for example, the dual-laser configuration can achieve 2 full builds (standard cylinder size 400 × 400 × 450mm) within one single day therefore significantly improves machine uptime and creates maximum throughput yield per floor area within the same time frame.

Meanwhile, with observation of the increasing demand for industrialized manufacturing of large-sized parts in a shorter lead time, Farsoon’s Multi-laser FlightTM Technology is also planned on its further application on the HT1001P CAMS platform with a build cylinder measuring 1000 × 500 × 450mm.

Expanding Material Portfolio for FlightTM Technology

We are glad to present the addition of two all new Farsoon PA12 based FS3300PA-F and PA12 based Glass bead reinforced FS3401GB-F powders into our material portfolio.

Developed for FlightTM Technology, the PA12 based FS3300PA-F is optimized for Fiber Laser processing. It is easy to process and versatile in its applications; it produces parts offering a good balance of mechanical/thermal/feature properties that can suit a broad array of industrial applications. The glass bead reinforced PA12 material FS3401GB-F is an ideal material for end-use applications that require functionality with excellent mechanical strength. Components made from this material are characterized with extraordinary dimensional stability, good thermal and abrasive resistance; making them well suited for industrial applications such as automotive engine system and electrical tools.

By using Farsoon’s latest PMS (Powder Management system) which integrates multiple powder handling process including used powder recycling & storage, new powder supply, high-speed mixing and sieving, the customer is able to achieve powder refresh rate up to 20% virgin material for both FS3300PA-F and FS3401GB-F, therefore enabling reduced manufacturing cost per part.

Besides expanding Farsoon’s PA12 powder family for FlightTM Technology, we are also excited to include a specialized TPU material from our partner LEHVOSS Group. The light grey colored, LUVOSINT® TPU X92A-1064 WT material has been successfully tested on Farsoon’s Flight 403P and 252P platform. The material offers convenient processing window, good recyclability; also, thanks to the superb elongation, high size stability of the built part, making it the natural choice for tailored shoes soles, complex tube geometries and many medical applications. The robust LPBF processing by Fiber Laser opens up new possibilities for rapid, industrial-scale TPU production.

With a culture of innovation and development speed Farsoon is open to collaboration with customers and partners to drive industrial additive manufacturing applications forward with the next generation of high-speed laser powder bed fusion manufacturing. Inquiries about our technology are welcome to visit our booth at TCT Asia (Hall 7.1, Booth H02) or contact globalinfo@farsoon.com for more information.

1Compared to Farsoon FlightTM Technology HT/SS403P Single Fiber Laser (1 × 500W) System

2Compared to Farsoon HS403P Single CO2 Laser (1 × 60W) System

About Flight Technology:

Farsoon’s Flight Technology™ or Fiber Light Technology takes advantage of powerful fiber lasers in place of the standard CO₂ lasers found in standard laser sintering systems. A fiber system is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system as compared to a CO₂ system Flight Technology™ also provides increased laser longevity which is key when considering ROI for manufacturing applications. In addition, with its increased power and energy absorption characteristics Flight Technology™ will be capable of accessing a much different range of process-able materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for future AM material and application development.

About Farsoon:

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2017, Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS), and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe. Farsoon is committed to developing AM towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, application and services. Learn more: www.farsoon.com