Rümlang (CH), Stuttgart (DE)

Farsoon Europe GmbH, based in Stuttgart, and Rapid Manufacturing AG, based in Rümlang (Canton of Zurich) in Switzerland, have signed a joint development agreement for the beta testing of Farsoon’s new FlightTM Technology. Subject is the development of an optimized system for use in the production of plastic components.

Figure 1: Mr. Alain Stebler, CEO of Rapid Manufacturing AG, and Dirk Simon, Managing Director of FARSOON Europe GmbH, signed a joint development agreement

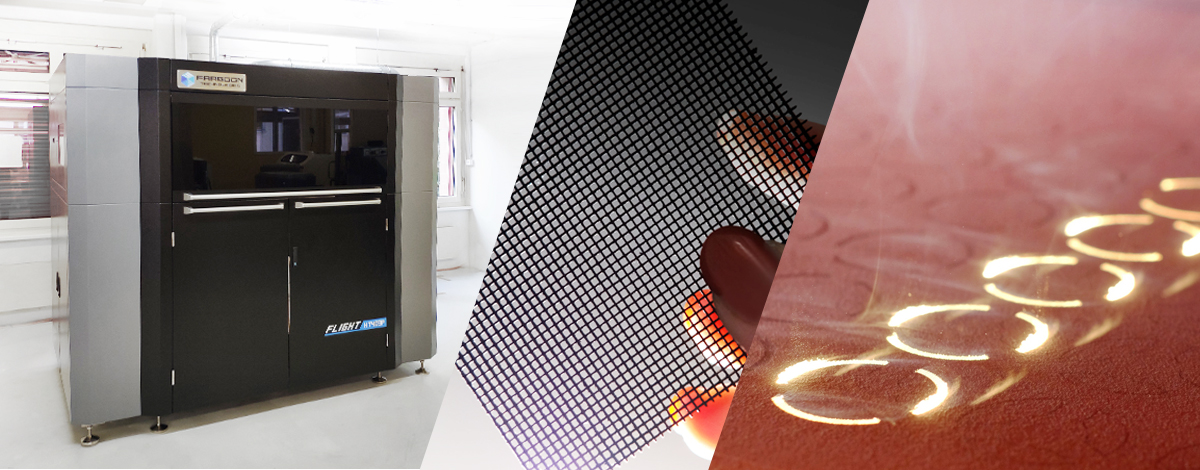

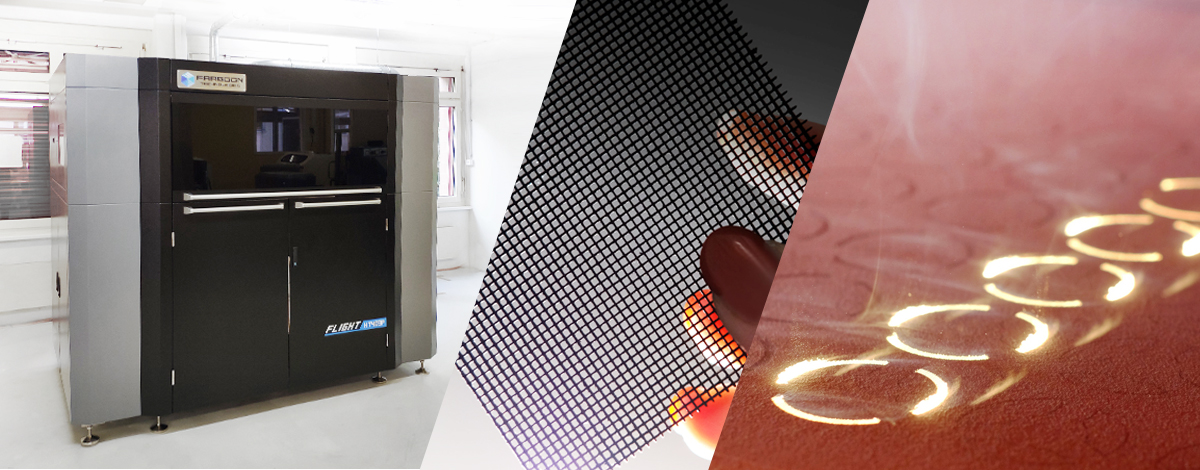

Farsoon installed the Flight-HT403P at Rapid Manufacturing in early October, and after initial successful testing, Rapid Manufacturing has begun producing components for interested customers.

“We are evolving our company in huge steps,” excited Alain Stebler, CEO of Rapid Manufacturing AG, says, “We are convinced that with the already 10-year-old FARSOON, we have found a reliable partner who helps us to offer high-quality parts at extremely attractive prices.”

Figure 2: Flight-HT403P installed at Rapid Manufacturing AG facility for high quality plastic manufacturing.

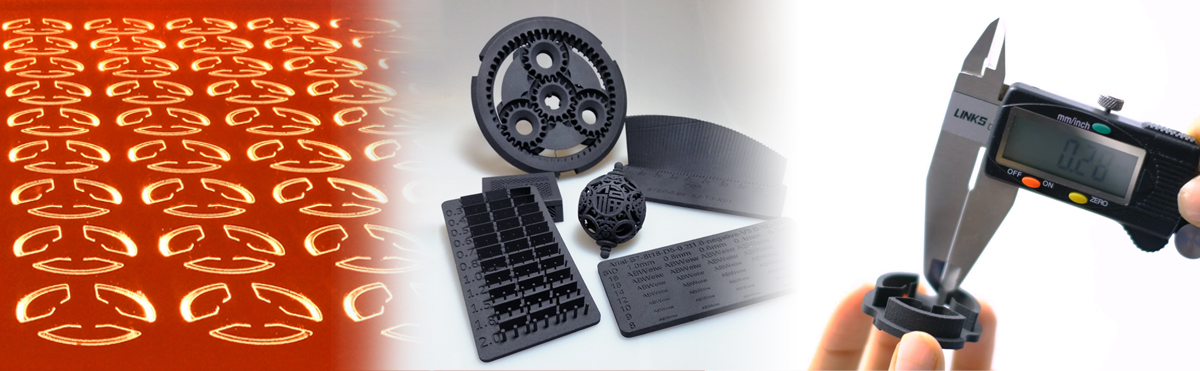

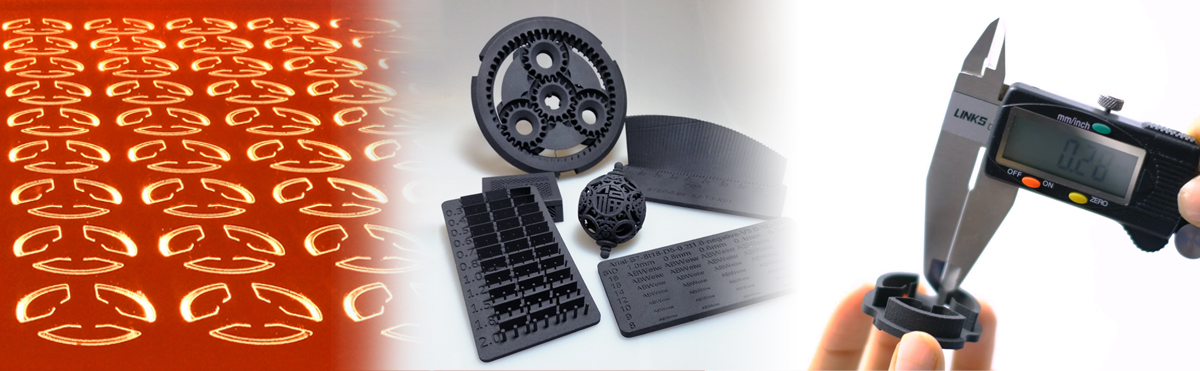

Figure 3: PA1212-based components manufactured by Rapid Manufacturing on the beta-Flight HT403P with fine feature resolution

Dr. Dirk Simon, Managing Director of Farsoon Europe GmbH adds: “We are impressed by the strong will power to increase the competitiveness of laser sintering, which Rapid Manufacturing is systematically implementing with the installation of our machine.”

Figure 4: Farsoon Headquarter based in Changsha, China. Dr. Dirk Simon, Managing Director of Farsoon Europe GmbH, Stuttgart.

The Farsoon Flight-HT403P has a build cylinder of 400 x 400 x 540 mm³. The system is equipped with a 500W fiber laser, which transforms the black polyamide powder very quickly into plastic parts. The parts produced on Flight-HT403P show not only good mechanical properties but also high feature resolution with small wall thickness and low surface roughness.

About Farsoon:

Farsoon Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Learning from the market about customer needs, Farsoon has moved to address the need for higher levels of productivity, improved feature details, and enhanced operational efficiency and flexibility. Farsoon’s latest Innovations like the Continuous Additive Manufacturing Solutions (CAMS) and the very accurate and ultra-fast Flight™ Technology stand for highest production rates and real industrial use of Additive Manufacturing.

Farsoon´s subsidiary FARSOON Europe Gmbh (Stuttgart, Germany) provide the whole range of machine portfolio as well as local service and maintenance activities.

About Rapid Manufacturing:

Rapid Manufacturing AG was founded in 2015 as a one-man business and specializes in the production of plastic parts in additive manufacturing processes. Within a short time, the company has grown into a dynamic Swiss SME. The application areas of the plastic parts from the production of rapid manufacturing are used as serial components, as prototypes and as machine components or as jigs & fixtures in production facilities. In addition, since 2017, the company has been the proud production partner of Götti Switzerland GmbH, a Swiss eyewear label, for the production of 3D printed eyewear.