October 16th to 23rd, Düsseldorf, Germany —— The world’s leading Trade Fair for Plastics and Rubber – K 2019, opens its gate to visitors at Messe Düsseldorf in Düsseldorf, Germany. During the event, Peak Sport Products Co., Limited (referred to as PEAK Sports) launched its latest 3D printed shoe collection with Wanhua Chemical Group Co., Ltd. (referred to as Wanhua Chemical). This innovative additive solution is supported by Farsoon Technologies Application R&D team with its Plastic Laser Sintering (PLS) system during the development, showcasing the latest application of 3D printing technology in the footwear industry.

Figure 1: THE NEXT Project press release at K2019 at Wanhua Booth. Image Courtesy: Wanhua Chemical

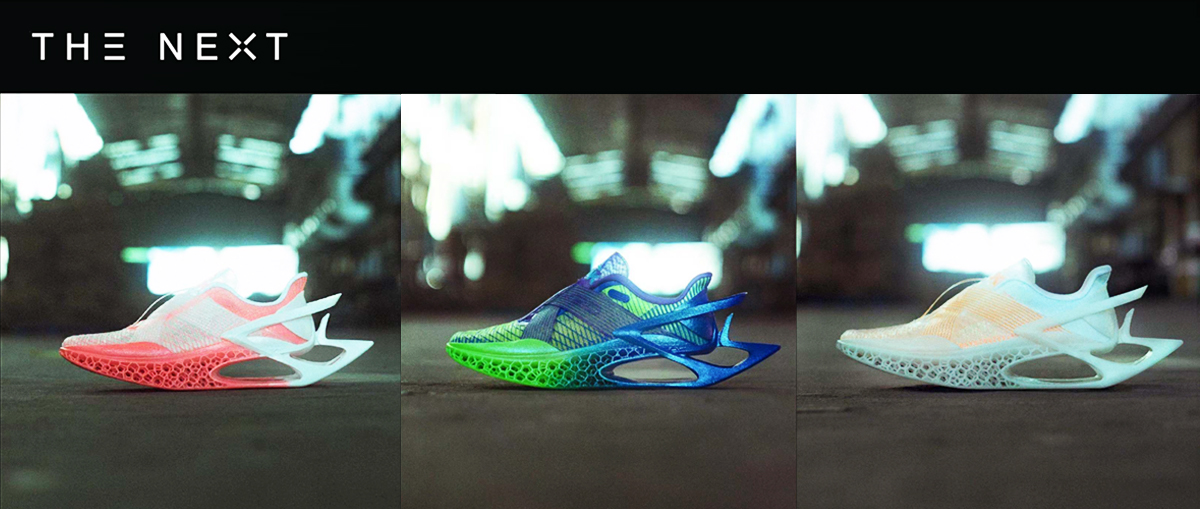

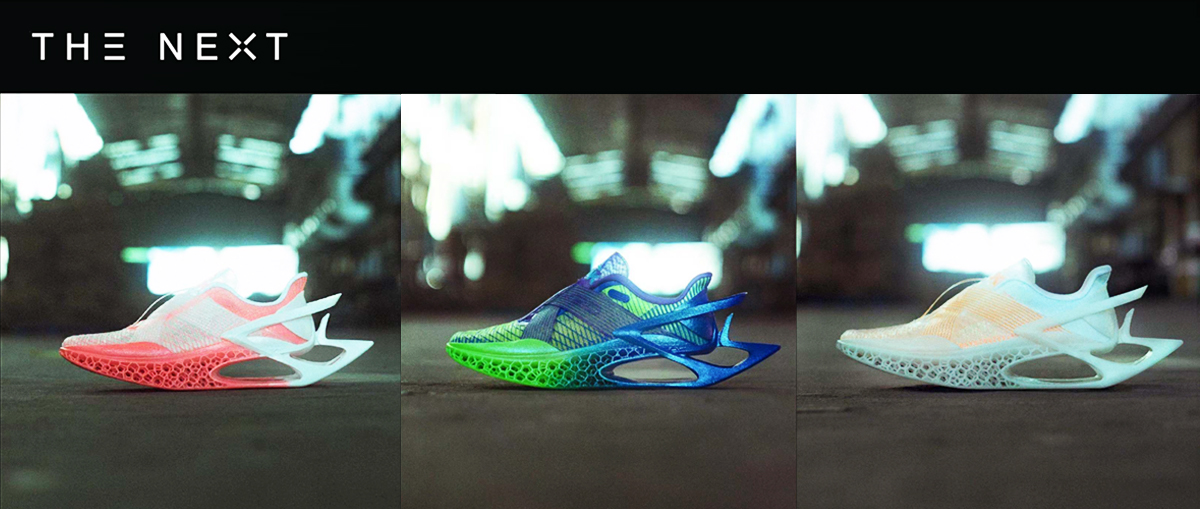

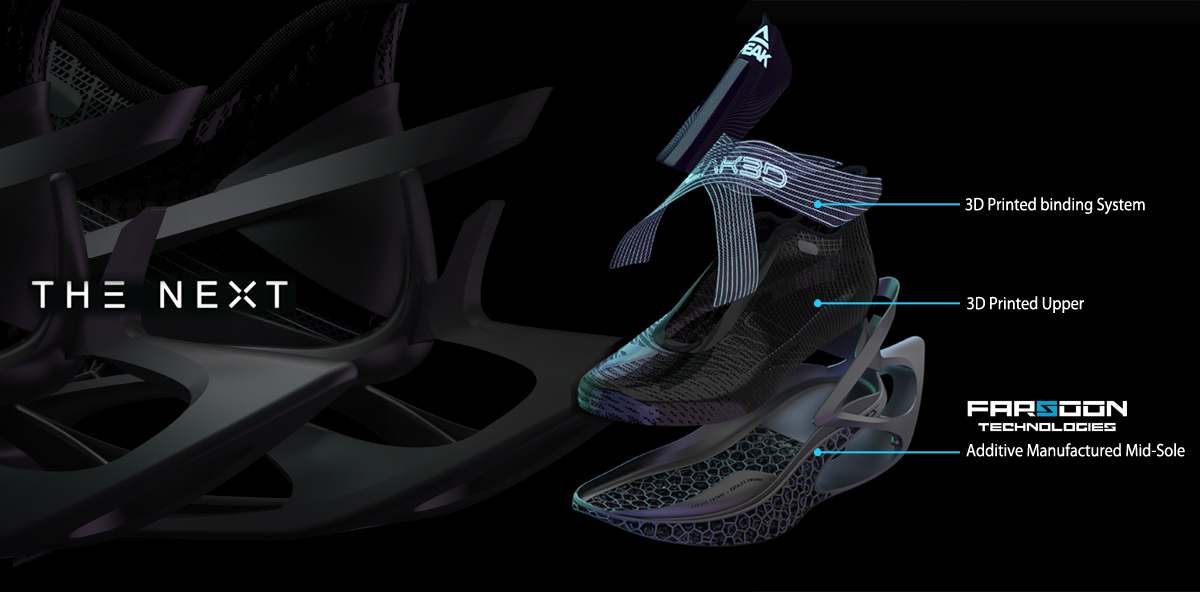

In recent years, 3D printed footwear has begun to be a commercial product across the globe thanks to the development of fast and cost-effective 3D printing technology as well as an expanding additive material portfolio for the application. Featured with various advantages in design customization, material properties, and sustainability over traditional products, 3D printed footwear has attracted continuous attention from manufacturers and consumers. However, remaining challenges including the additive material engineering, customization, integration of the shoe structure, as well as the in-depth collaboration in the value chain. In response to these pain points, PEAK Sports and Farsoon Technologies established a long-term partnership on co-developing the total 3D printing athletic footwear solution from the perspective of design, development, manufacturing, and integration.

Figure 2: THE NEXT Project supported by Farsoon additive technologies. Image Courtesy: PEAK Sports

Figure 3: Farsoon 3D printed mid-sole structure integration. Image courtesy: PEAK Sports

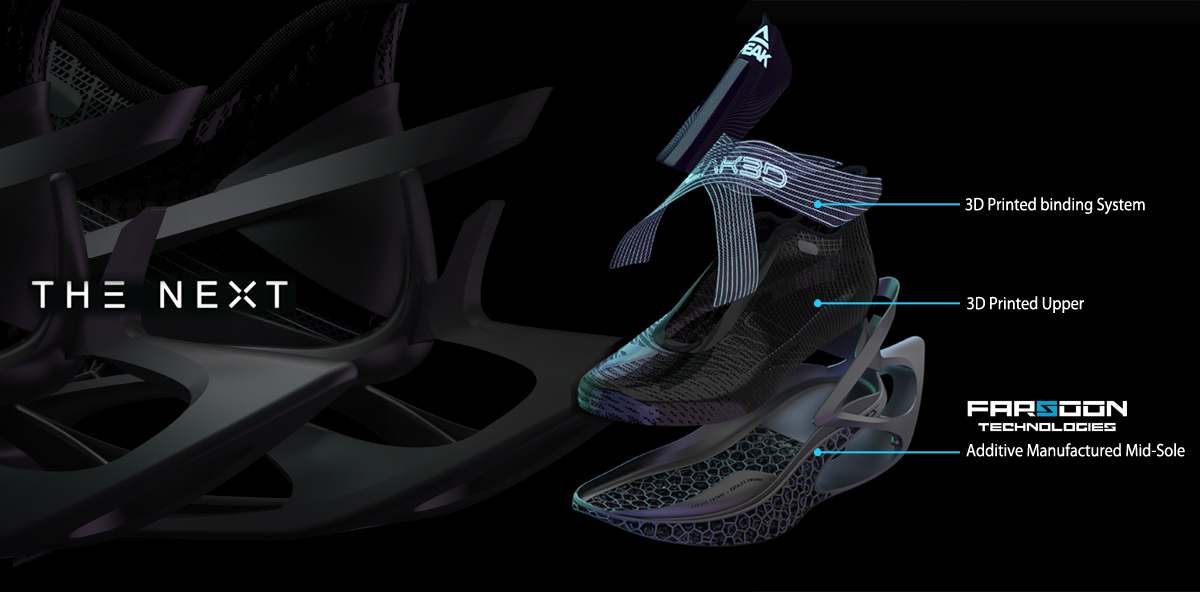

By combining the expertise of plastic laser sintering technology and athletic footwear engineering, Farsoon technologies and PEAK Sports have developed the mid-sole — a key component for comfort in footwear, using additive manufacturing. Traditional manufacturing of mid-sole is a complicated process. It is made from a flat rubber sheet composed of EVA (ethylene vinyl acetate resin) and foaming, separated into smaller pieces for high temperature pressure mold process. The foam expands and formed shoe mid-sole product.

Figure 4: As-Printed mid-sole by Farsoon 403P series. Image by Farsoon Technologies

While using additive technology for mid-sole manufacturing, the designer will be able to adopt more complex structures across the section, which optimizes for performance and stability of the integrated footwear during cushioning and bending. The additive design also helped to achieve the weight reduction of the shoe while ensuring durability. The introduction of the additive manufacturing has opened up a new horizon for the customization of the shoemaking industry.

Figure 5: As-Printed complex structure of mid-sole by Farsoon Plastic Laser Sintering Technology. Image by Farsoon Technologies

During the application development of the mid-sole, Farsoon and PEAK Sports carried out a large amount of engineering iterations and tests. PEAK team optimized the design structure according to the required strength and conditions, while Farsoon polymer Application R&D team developed advanced laser sintering processing parameters of TPU material for optimal product performance. During the development iteration, Farsoon and PEAK team also work closely with the footwear factory manufacturing, tailored the additive total solution to meet the real-world demands of productivity, cost and throughput. With the common goal of mass production, the Farsoon and Peak teams look forward to continued collaboration and developments for the additive shoeware market.

As an industrial grade plastic and metal laser sintering machine manufacturer, Farsoon is committed to develop the industrial additive manufacturing technology expanding the envelope of various applications and industries. With the announcement of 3D printing total solution for footwear, Farsoon Technologies has taken a solid step of introducing 3D printing in the shoemaking industry, offering more diversity and customization choices for both footwear manufacturers and consumers.

About Farsoon Technologies

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009 in China, is a global manufacturer and supplier of industrial polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial additive manufacturing technology in China with increasing growth in the international market. In 2017, Farsoon released the first of a new series of machines under the revolutionary Continuous Additive Manufacturing Solution (CAMS), and established Farsoon Technologies-Americas in Austin, Texas, USA. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany, to expand its direct operations to Europe. Farsoon is committed to developing additive manufacturing towards its true manufacturing potential and providing customers with best-in-class systems, materials, software, applications and services. Further information is available at www.farsoon.com. Please contact us at globalinfo@farsoon.com for any question.

About Peak

Peak is a group enterprise withholding the principle of “building an international brand, becoming a hundred-year enterprise”. Established in 1989, Peak mainly designs, develops, manufactures, distributes, sells, and markets its own sportswear products, including sneakers, clothing and accessories. Since the founding of the brand, Peak has focused on self-directed technological innovation. It currently holds more than 70 patents of practical novelties, and continuously releases products loved by consumers. In May, 2017, Peak released the first 3D printed sneakers in China; it also released the world’s first 3D printed sneakers for basketball, leading the trend of the industry. In December, 2018, Peak premiered PEAK-TAICHI, the self-adaptive technology for midsole in the world. Peak is committed to becoming an innovative brand leading China in sportswear technology, and continuously introducing innovative products to meet the needs of consumers.

About Wanhua Chemical

Wanhua Chemical Group Co., Ltd is a world-class chemical company with 4 manufacturing bases in Yantai, Ningbo, Zhuhai and Hungary and more than ten branches in Europe, the Middle-east, America, Japan, India, etc. Wanhua Chemical’s main business segments consist of three parts: Petrochemicals, Polyurethane, Performance Chemicals & Materials. Wanhua Chemical is one of the most competitive MDI, TDI and polyol producers in the world. With the mission of “Advancing Chemistry, Transforming Lives”, Wanhua Chemical will leverage its core competitiveness of innovation, industrialized devices, and solid foundation of excellent operations to provide its customers with more competitive products. Now, Wanhua Chemical has established R&D centers in Yantai, Beijing, Foshan, Shanghai, etc. Wanhua Chemical North America Technology Center in Houston was officially put into operation in 2017.