Oct. 24th, 2019, Changsha, China – Farsoon Technologies celebrated its 10th anniversary celebration as well as the AM Innovation & Industrialization Forum at their headquarters in Changsha. The full-day event attracted great attention from the Chinese and Global additive industry bringing together over 200 industry customers, partners, academic experts, media, as well as management level representatives from Farsoon Americas and Farsoon Europe, and Farsoon’s global channel partners. With 11 inspiring keynote speeches presented by AM industry and academic leaders, the ceremony participants shared their unique insights, innovative experiences and latest applications of AM technology.

Figure 1: Industrial attendees at Farsoon “10 Years of Innovation”

Figure 2: Farsoon’s history wall and brand-new lobby at “10 Years of Innovation”Event

The 10 years ceremony began with an opening speech by Hope Hou, General Manager of Farsoon, followed by Dr. Xu Xiaoshu, Founder and Chairman of Farsoon, introducing Farsoon’s roadmap of technological innovation in the past ten years as well as into the future. The new-released Farsoon brand video highlighted Farsoon’s philosophy “Open for Industry”, and comprehensive know-how through the entire additive workflow, cementing Farsoon’s place as a leading supplier of industrial grade additive machines in China with increasing growth in the global market.

Figure 3: Left: Farsoon Management Group at “10 Years of Innovation” Event. Right: Dr. Xu Xiaoshu, Founder and Chairman of Farsoon, introduced Farsoon technology roadmap for future development

After the brief ceremony, we had the honor of Dr. Stephen Liu, Former Director of Center for Welding, Joining & Coatings Research at Colorado School of Mines, and John Dulchinos, VP of Global Automation and 3D Printing at Jabil Group, as keynote speakers during the morning session, sharing the unique insight of additive technology in academia and industry.

Figure 4: Dr. Stephen Liu, Former Director of Center for Welding, Joining & Coatings Research at Colorado School of Mines, with over 40 years’ experience in metallurgical engineering, delivered a presentation titled” Materials Quality Assurance of 3D Printed and Welded AM Structures: Process-Material Interaction; Metallurgical & Mechanical Properties Characterization“, exploring the material research and quality control for AM application.

Figure 5: John Dulchinos, VP of Global Automation and 3D Printing at Jabil Group, delivered a presentation titled “Emerging Applications for 3D Printing Across the Product Lifecycle“, introducing Jabil’s roadmap of AM applications and future possibilities boosted by Farsoon’s Open systems.

The morning presentation session was followed by a campus tour which showcased the Farsoon facility, highlighting the theme of innovation and industrialization with Farsoon’s latest applications in the industries of aerospace, automotive, medical, denture, molding, consumer products, etc. The guests visited Farsoon’s brand-new showroom, application center, material testing lab, machine production facilities as well as polymer material production facilities.

Figure 6: The guests attended campus tour at Farsoon facility viewing latest additive developments and industrial applications.

During the even guests became the first to publicly view Farsoon’s new FS301M metal laser sintering system. Farsoon’s openness to truly co-innovate by working with customers has led to the development of a highly productive and industry ready system. The Farsoon FS301M features a 305 × 305 × 400mm build cylinder suited for larger-sized industrial applications as well as versatile single or dual laser options for improved productivity and efficiency. With enhanced powder handling safety offered by the integrated powder feed connector, the material loading and un loading process can be accomplished under a inert environment without the need to expose the environment or user to potential contamination or hazards. Combining with an integrated long-lasting filtration system, the FS301M features a compact machine footprint and designated operation access for a flexible factory layout and good serviceability. The Farsoon FS301M system will be first showcased at Formnext in Frankfurt at Farsoon booth 11.1-C68. on Nov. 19-22.

Figure 7: Farsoon’s latest development of user-friendly industrial metal system: FS301M

In the afternoon, Jack Cheng, DGM and Head of Global Sales and Marketing of Farsoon, announced the opening of AM Innovation and Industrialization Forum in the afternoon, followed by 9 guest speeches by the AM leaders in the industries of aerospace, automotive, industry, medical and institute. From different perspectives of material, system, process, software, design and application, the participants shared their latest achievements and applications of AM in their respective fields, and highly appraised Farsoon’s open mindset and consistent focus on customers’ needs.

Figure 8: Farsoon AM Innovation & Industrialization Forum

Figure 9: Dr. Dirk Simon, Managing Director of FARSOON Europe, gave a presentation titled “Beta-testing of Farsoon HT1001P with FKM in Europe: Partnership to leverage industrial laser sintering” on behalf of FKM Sintertechnik, which announced the completion of Farsoon’s HT1001P Beta testing program at site.

Figure 10: Volker Hammes, Managing Director at BASF New Business GmbH, gave a Presentation titled “Industrial AM requires fit-for-purpose 3D printing solutions at B2B economics“. As early as 2015, Farsoon and BASF reached a strategic agreement to develop high-temperature materials based on Farsoon’s open system, afterwards released Ultrasint PA6 X028, Ultrasint PA6 X043 materials and high-temperature polymer system HT403P.

Figure 11: (Left) Dr. Michael Wu, Advanced Materials Manufacturing Project Leader at Solar Applied Materials Technology Corp., gave a presentation titled “ NiTa Alloy Sputtering Target Built by Selected Laser Melting for Hard Disc Applications“, introducing the achievements with Farsoon’s metal AM solution in the NiTa Alloy Sputtering Target for hard disk application.

(Right) Dr. Yong Chen, Professor of Industrial and Systems Engineering and Aerospace and Mechanical Engineering, University of Southern California, gave a presentation titled “Recent Progress in Biomimetic Additive Manufacturing Technology: From Materials to Functional Structures“, indicating the development of biomimetic design and additive manufacturing is changing the patterns of design and manufacturing.

Figure 12: (Left) Sebastian Bersch, Business Development Manager – Manufacturing at Siemens, gave a presentation titled “Industrializing Additive Manufacturing Together“, introducing how Siemens PLM software integrates with Farsoon’s open system to explore the potential of AM in the industrial scale.

(Right) Xiaodong Jiang, Founder and General Manager of SAPW Technology, gave a presentation titled “Systems and Applications in Industrial Additive Manufacturing”. SAPW was founded in 2014 in Wuhan, with experienced core team from automotive industry. The main business includes industrial design and modeling, 3D printing and rapid manufacturing, mold design and manufacturing. With investment of multiple Farsoon’s plastic and metal AM systems, SAPW supplies industrial products to leading automotive brands’ passenger cars and commercial vehicles. SAPW is one of the earliest adopters of industrial scale functional parts additive manufacturing for series production.

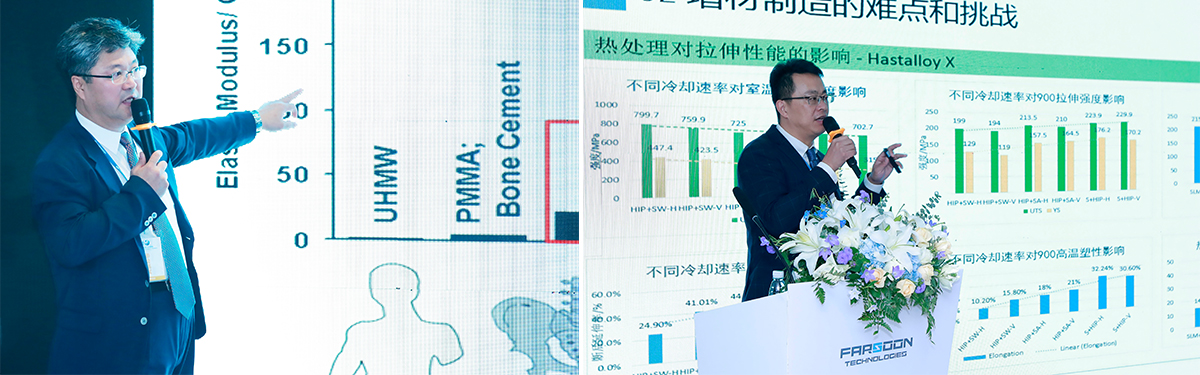

Figure 13: (Left) Dr. Changwoo Lee, Managing Director (Gangwon Regional Division) of Korea Institute of Industrial Technology (KITECH), gave a presentation titled “The Medical Industry Application of Ti and Ti Alloy in Additive Manufacturing”, stated that KITECH has carried out various researches on 3D printed medical materials thanks to Farsoon’s open metal AM solutions. Among which titanium alloy and other materials have passed Korean FDA certification for surgery implementations

(Right) Wei Li, Sales director of Falcontech, gave a presentation titled “Latest Industry Application of Additive Technology in the Aerospace Industry Manufacturing” Falcontech was founded in 2012 in Wuxi, China, is a leading service bureau of metal additive technology for the aerospace and aviation industry. Farsoon and Falcontech established a strategic partnership to jointly promote the industrialization of AM in the aerospace industry

After the nightfall, all the guests attended the “Farsoon Night” dinner at Farsoon campus square. Dr. Xu Xiaoshu and Mr. Hou Xingwang, the investor of Farsoon and the chairman of Sunwalk Group, delivered greetings speeches.

Figure 14: “Farsoon Night” Dinner party

Farsoon team would like to thank all customers and partners for their continuous trust and support. We also would like to express our sincere appreciation to all Farsooners around the globe, we would not have been able to come this far without all your diligence and hard work. Let’s toast to a brilliant future for Farsoon in the next decade!