The growing popularity of 5G has seen its expansion around big cities and other developed regions. 5G adoptees have experienced increasing benefits in both the industrial and consumer market, with faster, more secure, and more efficient communication. However, there is untapped potential in the large automotive market. With the recent popularity of intelligent systems amongst high-end cars, safety systems, adaptive cruise control, crosswind stabilization supported by automotive antennas systems are now standard for luxury vehicles. Unfortunately, when we look at a larger majority of less high-end automobiles, the high cost of the antenna devices has limited the growth of this application with the communication often interrupted by weather and range. These challenges are exacerbated when it comes to emergency services such as fire-fighting, rescue, energy management and power-grid operations. To ensure the best efficiency and reliability of data communications, antennas and terrestrial device need to stay integrated and connected anytime, anywhere.

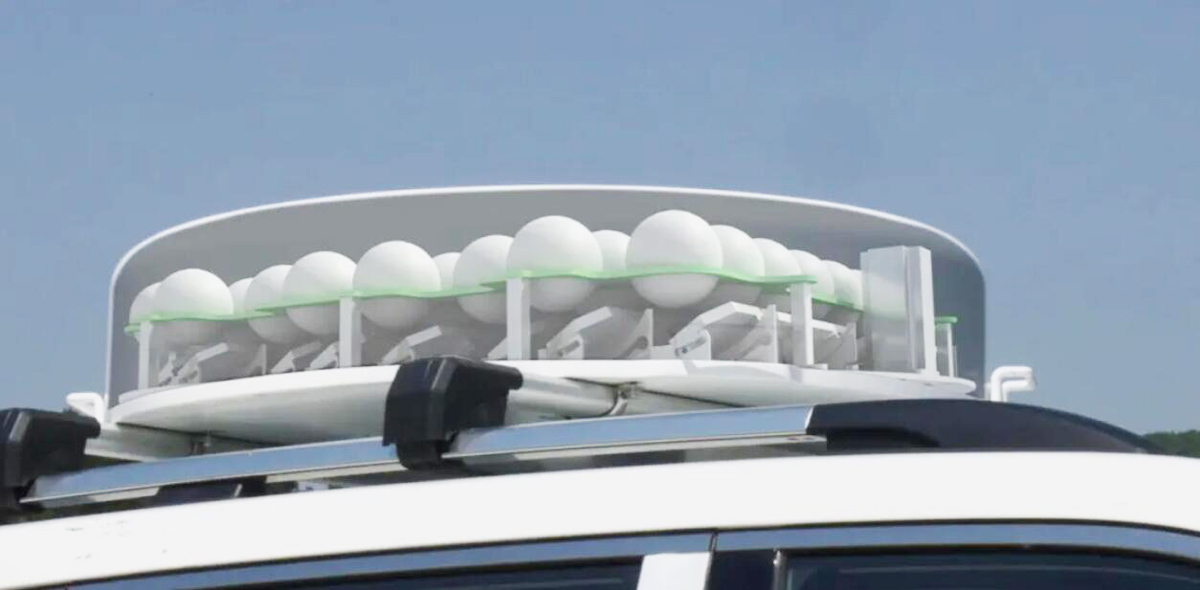

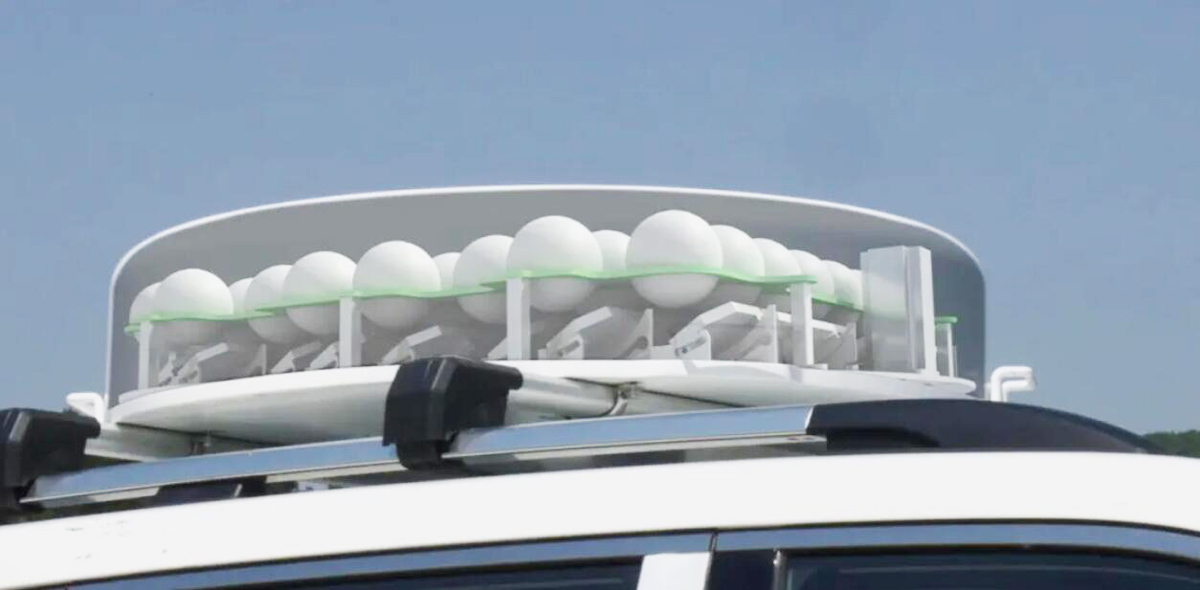

Figure 1: Rhosoon vehicle antenna system mounted on car rack. Image courtesy: Rhosoon.

Rhosoon Intelligent Technology Co., Ltd. (refer to as Rhosoon) is a leading civil antenna & terminal solution provider specialized in customized vehicle communication antennas, terminals, and core components design and manufacturing. The traditional vehicle-mounted antennas system is usually equipped with a variety of expensive ultrasonic, infrared, and optical sensors plus power generating devices, making it large in volume and very heavy. Committed to offering affordable and reliable antennas communication systems for vehicles, Rhosoon has been innovatively using 3D printing technology since day 1, from product planning, design, prototyping, optimization, verification, and now has achieved 100% series production with Farsoon’s 403P laser powder bed fusion system.

Optimized structure and performance with SLS technology:

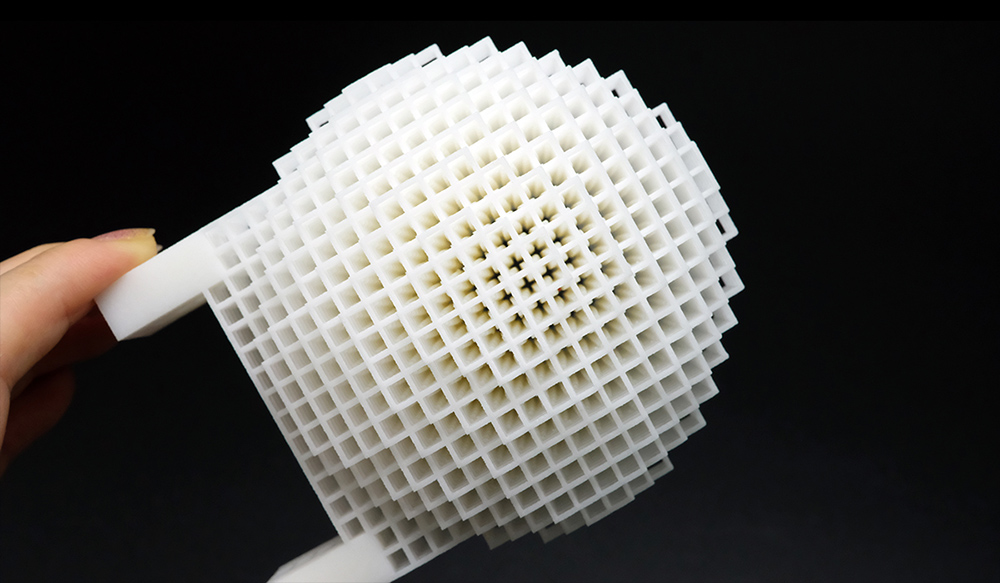

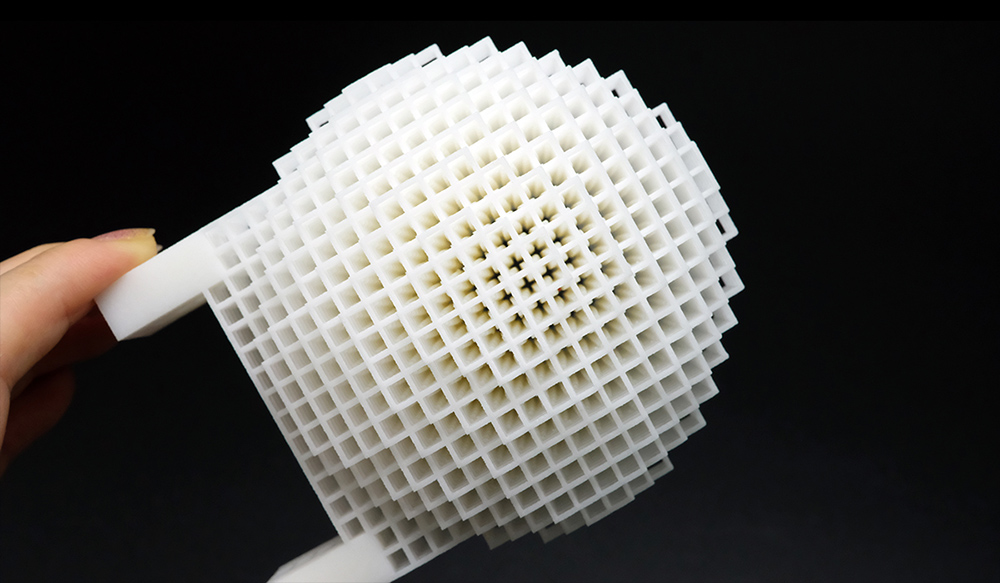

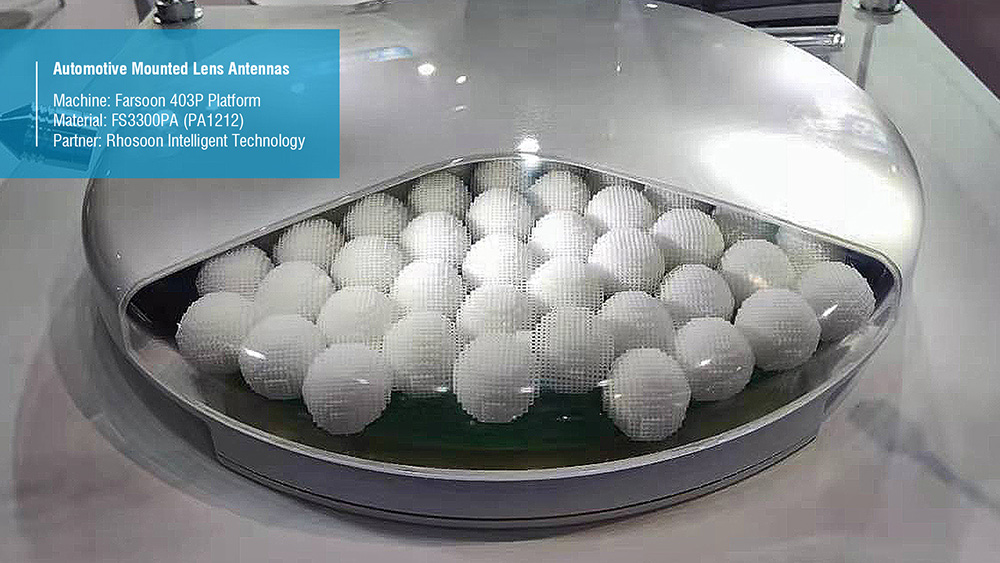

Comparing to large and heavy traditional vehicle antennas systems, Rhosoon’s innovative solution offers a significantly smaller, 3D printed device replacing complex equipment, and offering even better performance. This 3D printed device has implemented the Luneburg lens concept of design, which features a spherically symmetric gradient-index design for a radially decreased index refraction from the center to the surface, which allows for good convergence and directional refraction of electromagnetic waves and capable of relaying multiband signals.

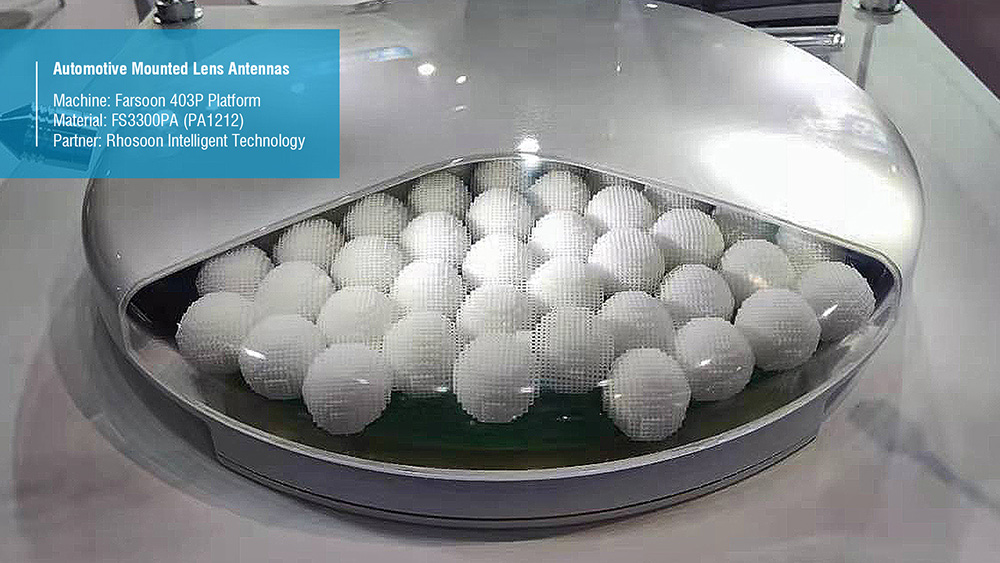

Thanks to the powerful laser powder bed fusion process, Farsoon offers fabrication of Luneburg lens antennas in one-piece without any supports. Manufactured with Farsoon’s FS3300PA, a PA1212 material, the printed antennas which exhibits stable and good dielectric constant performance (between 2.5-3) during the functional verification. The high-quality FS3300PA material with laser powder bed fusion processing also shows superior mechanical properties and improved durability under high-temperature conditions compared to other additive technologies such as FDM.

Figure 2: 3D printed Rhosoon Luneburg lens with complicated details

Accelerating design to market circle:

The Luneburg lens design features a multi-layered structure within an extreme compacted volume, with varied layer thickness and many detailed features to offer different electromagnetic wave refraction by each layer. Using Farsoon 3D printing technology from planning, development, prototyping, simulation, testing to manufacturing, Rhosoon is able to significantly reduce design-to-market time, and simplify the manufacturing process by additively producing the complex antennas structure with fine detail resolution and quality control. Farsoon’s laser powder bed fusion technology also enables Rhosoon to develop highly customized 3D printed antennas designs to best suit each application’s needs. Since the first 3D printed product was installed in late 2018, Rhosoon has successfully completed a number of projects featuring a wide range of customized antennas.

Figure 3: 3D printed Luneburg Lens installed in antennas system. Image courtesy: Rhosoon.

Reduced cost of manufacturing:

“Farsoon laser powder bed fusion technology has saved us so much investment cost that was required for production tools and molds, especially when it comes to customized products and small batch production. Take an antennas product with 80mm diameter for example, now we can achieve 48 high quality pieces production per day on a single Farsoon 403P machine – It is a perfect solution for economic small batch fabrication and spare parts.” Says Rhosoon.

As of today, Rhosoon’s novel 3D printed vehicle antennas solution has successfully offered affordable, high performance communication service for remote areas with weak network coverage, and provides reliable support for emergency operations under extreme conditions. “With the rapid development of the antennas and 3D printing technology, we envision a more compact communication device as small as a notebook, and with a true economy of cost to enable wide scale adoption of satellite-terrestrial communication integration in the near future.” Says Rhosoon.

Fiture 4: Rhosoon antennas system showcased at TCT Asia 2021.

About Rhosoon:

Rhosoon Intelligent Technology Co., Ltd. is a leading civil antenna & terminal solution provider specialized in customized vehicle communication antennas, terminals, and core components design and manufacturing. Empowered by a team of experts from new materials, new process, integrated circuits, microwave & communication systems and other key technologies, Rhosoon is dedicated to introduce the next generation of antennas & terminal solutions to global customers.

About Farsoon:

Farsoon Technologies, founded in 2009 by Dr. Xu Xiaoshu, one of the early pioneers of laser sintering technology with more than 20 years’ experience in the industry, now is a leading machine supplier of industrial Metal Laser Melting and Plastic Laser Sintering systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. With clear vision “Open for Industry”, Farsoon is committed to supporting the industrial production with open systems, materials, parameters and applications. For more information, please visit: http://www.farsoon.com

DOWNLOAD SUCCESS STORY